Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Aluminum has found wide application in the modern world. This metal is characterized by light weight, ductility and ductility, which allows it to be used in many industries. Its melting point is 660°C. In production, aluminum casting is often used, thanks to which all kinds of parts are made.

Technological process

People have been smelting aluminum for a long time. It easily acquires anyform, therefore it is simply indispensable in the global industry. Today, many steel mills use high pressure casting technology. It is created in a special chamber using a piston, which is affected by compressed air, emulsion or oil, accelerating the movement. The molten metal enters the high-strength steel mold at a speed of about 50 m/s, which ensures that it is completely filled.

Die casting aluminum has many advantages, including not only increased productivity, but also high precision of the finished product. The technology is used to produce important parts in instrumentation, mechanical engineering and aircraft manufacturing.

Aluminum casting at home

A simple part of this metal can be madehimself. Everything you need for this can be found in the home workshop.

First of all, you will need a box with a lid where the molding earth will be stored. Aluminum casting is usually done using mixtures of sand and clay. For small parts, you can take ordinary silica. It must be sifted and poured into a prepared wooden box.

In the process of work, the following tools will be needed: a wooden spatula, tweezers, hooks, scalpels, brushes, brushes and a trowel made of high-quality steel and having a smooth surface.

Aluminum casting at home involves pouring metal into molds. They can be made from a wooden box.

Making molds

Forming of the future part takes place in two flasks (frames). To make them,you need to remove the bottom and lid of the box and cut it with a longitudinal saw into two parts of different heights. In the resulting flasks, it is necessary to drill two vertical holes on opposite walls and insert coke rods into them. When closing the box, the cokes protruding from the bottom of the box should go into the holes drilled in the top frame. This will allow you to accurately fix the flasks relative to each other.

With the correct manufacture of the mold for casting aluminum in the ground, a cavity should be obtained that will completely copy the cast part. It is done by pressing one side of the copy of the product into the ground of the upper flask, and the other into the surface of the lower flask. The frames must lie onstrong shield. A copy of the part can be made from wood or foam.

The backfilling of the molding earth should be gradual. Each new layer should be well tamped, otherwise the sifted earth will not hold its shape. It remains to make a few gas outlet holes and insert a sprue through which molten metal will flow. Now you need to let the earth dry well.

Pouring aluminum into a mold

Before you finally assemble the form, you must carefully examine it andmake sure there are no lumps of earth. Aluminum casting will give an excellent result only if the recess perfectly repeats the product. The joint formed between the lower and upper flasks is recommended to be covered with clay so that the liquid metal does not overflow over the edges of the recesses. After that, the upper flask is superimposed on the lower one and fixed with cokes.

Aluminum needs to be melted in a tin by putting it on a burning furnace. When the metal stops sticking to the poker lowered into it, it can be removed from the fire and poured into the mold through the sprue.

After waiting for cooling, it is necessary to remove the item from the ground. Usually, after this, additional processing of the product is carried out, including cutting off excess protruding edges and turning.

Aluminum casting is a very exciting and rewarding process. Thanks to this technology, small parts can be made by yourself, which will give you a pleasant experience and save money.

Recommended:

DIY photo frame decor: ideas, instructions for doing it

In the article, we will consider several interesting options for decorating photo frames with our own hands with a photo, we will tell in detail the sequence of work and acquaint the reader with the materials that need to be prepared before starting it

How to make DIY painting by numbers?

Painting by numbers is a way of creating a picture in which the image is divided into shapes, each of which is marked with a number corresponding to a certain color. You paint in each area with the desired shade, and eventually the picture becomes complete. The completed painting by numbers will help you learn to analyze the subject and observe how the whole composition is obtained from the colored areas

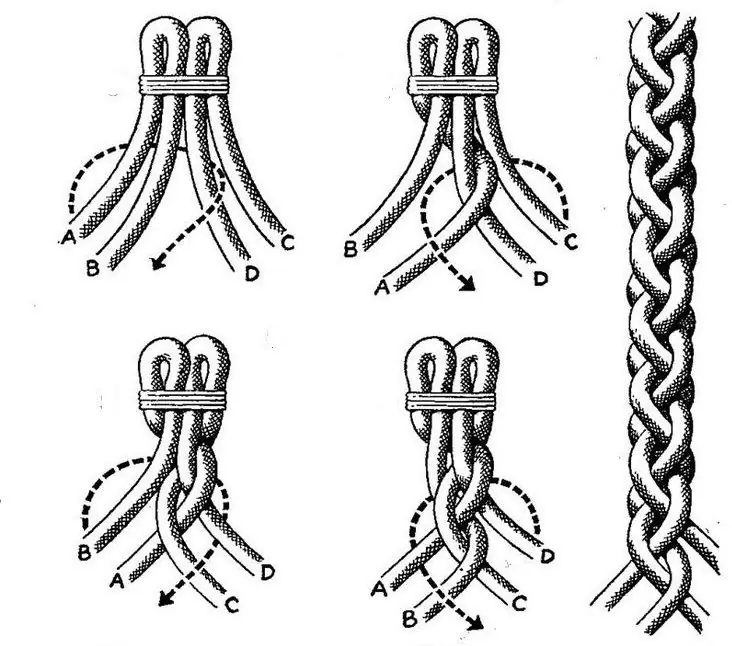

DIY leather bracelets: master class

Bracelets are presented on store shelves in a wide range, so choosing a stylish addition to the image is not difficult. However, many prefer exclusive jewelry, so they decide to try their hand at creating accessories. Making a leather bracelet with your own hands is quite simple, even a novice craftswoman can handle it. In this material, we will tell you in detail how to weave women's and men's bracelets, what materials will be needed for work

Casting in chess - how to do everything by the rules

Castle in chess is a double move performed by the king and rook, which have never moved in a game

Decorative bronze: mold casting

What kind of material is bronze? Casting from this alloy is carried out according to the usual scheme or are there any special features? What technologies are needed for casting at home?