Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

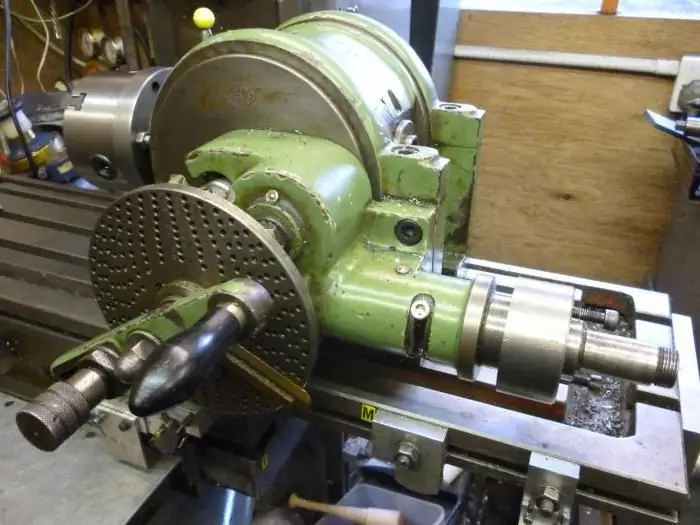

Dividing head of universal type (UDG) is used for processing metal blanks on a milling machine. This element allows you to carry out several types of operations for finishing products, taking into account the peculiarities of their configuration, and is used for the production of complex parts. As a rule, the equipment is equipped with this device as standard. Otherwise, you will need to select the correct model according to the characteristics of the existing turning fixture.

Purpose

The dividing head allows you to transform the workpiece into the desired configuration by shifting the part relative to the axis of the machine equipment.

UDG is fixed on the frame of the unit by various types of fasteners, depending on the type of nozzle. The working position is adjusted with the help of movable handles and a disk, which is equipped with holes for fixing the dividing unit.

Features of the instrument in question:

- Milling surface grooves. This process does not require perfect precision,taking into account the correct control of the depth and width of the workpiece.

- The ability to create faces on parts. This operation is expedient in the manufacture of nuts with non-standard parameters, as well as working tools and workpiece shanks. Such manipulations require high precision.

- Carrying out milling work on the processing of grooves and slots. In this case, significant movement of the workpiece may be required.

Features

Universal dividing head is used to increase the speed of work. However, it should not be subject to constant reinstallation. Changing the position in relation to the cutter is performed by placing the device in the desired position. Particular attention should be paid to this process when forming screw-type grooves. Their manufacture is possible only with the use of high-precision modification of the assembly.

Before buying a dividing head, be sure to check its compatibility with your existing machine. Any do-it-yourself modifications to the design and unprofessional alterations may adversely affect the final quality of the product.

Specific properties

Taking into account the specifics of the tool in question, you should choose a dividing head for a particular milling machine. Elements are divided into several types and types, differing in the method of installation, size, principle of operation and technical parameters.

Specialattention is paid to the accuracy of the implementation of the work carried out. In addition, the complexity and accuracy of setting the parameters of equipment for operation are taken into account. This approach allows you to choose a modification with high accuracy and permissible errors. With certain skills and the right tools, UDG can be done on your own.

Classification

Dividing heads for milling machines are classified as follows:

- Simple model. It is lightweight and easy to handle. The main part is the spindle, which fixes the workpiece and is connected to the disk limb. This element has several holes that allow you to shift the workpiece relative to the milling axis.

- Combined options. The devices are adjustable with a handle. With a larger number of clicks, the distance of the center axis of the workpiece from the cutter increases.

- Universal samples are complex equipment that requires adjustment through the participation of a disk element and a handle. The process is carried out with the participation of differential gears.

Marking

Deciphering the marking of the dividing head will determine the model and the possibilities of its use. Using the example of modification UDG-40-D250, consider the designations:

- UDG - universal dividing head.

- 40 - gear ratio indicating the number of revolutions of the spindle handle when turning 360 degrees.

- D250 - the maximum allowable dimensions of the workpiece.

Samples of the UDG category more oftenmost commonly used to form edges and surfaces of increased complexity.

Setting dividing heads

Possible tool transitions depend on the type of device and its technical parameters. The processing accuracy is determined by the divisions of the available scale, the indicators of which correspond to the 7th (GOST-1.758) or 9th (GOST-1.643) calibration level.

The main tuning process is to determine the dimensions of the sector of the dividing circle. In addition, the diameter of the circle and the number of compartments into which it is divided are taken into account.

The element setup process consists of the following steps:

- Transform 360 degrees full diameter into required number of sector divisions.

- Determine the sine of the resulting calculated angle.

- The device disk is set according to this indicator.

- The body of the block is fixed with a handle or a clamping mechanism, after which the working part of the tool is mounted.

The formula for calculating the required angle can be found in the user manual for the UDG. The workpiece to be processed is fixed on the mandrel of the machine, the longitudinal displacement of the table is performed, and the finishing is carried out. The feed step is affected by the type of processing. To increase productivity, after the completion of the next work cycle, use the accelerated return of the table to its original position. The elements are fixed in the measuring holes of the disk by means of springs.

DIY dividing head

high cost. In this regard, the dividing head for simple operations can be made independently. You will need a set of the following components:

- A worm-type gearbox that can be picked up from the equipment of old machines or machined with your own hands.

- Diameter lathe chuck (suitable size is 65mm in diameter).

- Restriction screw.

Before the production process, the dividing part must be adjusted. Any standard part or a turned figure of a certain format will help with this. After a comparative test with an analogue, an additional calibration of the instrumentation is carried out. The cost of a do-it-yourself dividing head will be an order of magnitude lower than the factory counterpart, the price of which starts at 40-50 thousand rubles.

Recommended:

What is a camera aperture? Principle of operation and aperture setting

To learn how to take beautiful and, not least, high-quality pictures, you need to know the fundamental parts of photography. What if you want to focus the viewer's attention on a particular area of the photograph? And what is a diaphragm? These are some of the questions beginner photographers ask

Assessment of icons in a silver setting. Evaluation of vintage icons by photo

Antique Orthodox icons are of great interest to collectors all over the world. It is not only an object of aesthetic and spiritual pleasure. Antique icons are a win-win investment. As a special kind of antiques, they are highly valued in the market, and their value increases every year

How to make a mini reborn? Master class on creating the head and face of a mini-reborn with your own hands

Mini reborn is a mini version of dolls for girls. We are all familiar with Barbie or Bratz dolls, but mini reborn dolls are a completely different kind of doll. These are small newborn babies. They are depicted in those positions in which children most often lie, sit or sleep. In a small reborn doll, each wrinkle and part of the baby’s body is so accurately and reliably conveyed that sometimes there is a slight embarrassment from almost one hundred percent similarity with a real baby

Medals "For Valiant Labor": description and price

In the USSR, awards given to people for labor exploits were a kind of gratitude from the state. They were awarded both to ordinary workers and collective farmers, as well as engineers, workers in science and art, public, party and trade union leaders, who, to the best of their ability, brought the victory of the Soviet Union over Nazi Germany closer as best they could. There are two types of the medal "For Valiant Labor", which will be discussed in this article

Machine seams: technology and types. Machine seams: connecting, edge

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible