Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible. It is well tolerated not only by long-term use, but also by frequent washing. The main thing is to know in which case how to sew.

Seam classification

Even at school, children learn a variety of machine seams. Grade 7 even learns how to do them with a sewing machine.

All seams are divided into three types: connecting, edge and finishing. Connecting seams are designed to fasten together different parts of the future product. Such machine seams are considered basic. Of course, there are quite unusual ones among them, but they are used extremely rarely.

Edge seams are designed to shape the edges of the product so that they do not fray and do not spoil the appearance. They are just as important as the connectors. Although there are some techniques when the edges are left unsheathed. But these are special cases.

Finishing seams rarely connect parts of a product or shape its edges. They are designed to decorate and create unusual effects. Machine finishing seamsare somewhere in the middle between embroidery and regular stitching.

Varieties of connecting seams

In the specialized literature, the terminology of machine seams is quite extensive, and sometimes a little synonymous. One and the same seam may have several names, but the technology of its execution does not change from this.

Tailors distinguish the following main types of seams:

- Stitch and hem are used to easily connect two pieces of fabric.

- Double inverted seam is appropriate in bed linen and children's clothing. It does not have such a rough scar, and the edges of the fabric processed in this way are not frayed.

- The boring stitch is used in those places where the borders of the fabric connection need to be hidden as much as possible.

- The sewing seam has two options. Most often it is found on jeans. Therefore, its second name is denim.

- A set-up seam is necessary in order to securely fasten two parts in the place where they will have the maximum load.

As you can see, machine seams are very diverse, and they are used for specific tasks. In order for them to have maximum efficiency, it is necessary to correctly observe the technology for their implementation.

Fixed and overturned seams

The main machine seams that connect the details of garments are stitched and turned. In fact, these are variants of one seam used for different purposes.

The seam is based on a thread connecting stitch. At the same time, the width of the seam itself directly depends on the quality andproperties of the fabric, as well as on the purpose of using the product. The width is the distance from the edge of the part to the line.

Its technology looks like this: the details of the product are folded with their faces to each other and stitched at a previously defined distance from the edge. Next, the sections can be ironed, that is, laid out on different sides and smoothed with an iron, or ironed in one direction or on the edge.

For collars, straps, pocket flaps and cuffs, it is more appropriate to use a backstitch. First, the product is stitched with a stitched seam. Then, on the front side, it is necessary to sweep the product so that a small edging is obtained - 1-2 mm wide. But this is not an axiom. For example, the overcast seam can be up to 8 mm if it is a crumbling fabric. These are the types of machine seam that are the main ones for tailors.

Denim seam

This is a very strong and reliable seam. Everyone who has jeans at home has seen him. And everyone has them. In any manual, you will find different types of machine seams, the table of which always contains several varieties of sewing (denim) seams. Its advantage is also that it looks equally beautiful both from the front side and from the wrong side.

The technology of its manufacture is clear and relatively simple. Fold the two pieces right sides inward. In this case, the lower one should protrude at a distance of about 1 cm from under the upper one. We sew the parts together at a distance of about 7 mm from the edge of the top. The first stage of work on the seam is completed.

The lower cut of the product must be bent to the very line andcover with top layer of fabric. Turning the product over to the other side, we sew a fold at a distance of 1-2 mm from its edge on both sides. We will have a fold with two parallel lines that look the same from the front side and from the wrong side.

Other joining machine stitches

Fixed seams are widely used when connecting pockets or yokes with the product. They have an average degree of strength. At the same time, a high level of sewing skill is needed, as uneven stitching will spoil the appearance of the product.

This seam comes in two types: open and closed. For a closed edge, the part is pre-ironed and basted to make it easier to work with. The seam technology is simple. The necessary detail is superimposed on a pre-planned place and sewn with a regular or decorative stitch. The sewing area is smoothed out well.

The topstitched seam belongs to the connecting-decorative. It is performed on the basis of a stitched seam. Its width should be slightly larger, since on the wrong side the edges of the seam are smoothed out and sewn parallel to the main one. The distance can be anything. The main thing is to observe two most important conditions:

1) the seams must be strictly parallel with respect to the middle;

2) the distance from the center seam to the side seams should be perfectly equal.

Otherwise, the entire decorative effect will disappear, and there will only be a sloppy product.

Edge Finishing Methods

It is important for any product to correctlytrim its edges. For industrial purposes and professional tailors, there is an overlocker for these purposes. This machine allows you to sheathe the edge so that it will never crumble again. But outwardly it does not look very neat. Therefore, visible edges lend themselves to additional processing.

For this purpose, both bending the fabric and its edging are used. It depends on the type and structure of the material with which the master works. Also, the performance characteristics impose their own characteristics on the processing of edges.

The most commonly used are a variety of hem stitches and edging machine stitches. Grade 7 in schools analyzes the technologies of the main ones. Therefore, every woman knows approximately how they are performed and when it is better to use them.

Sometimes you can combine them with finishing seams or decorative stitches for a more decorative effect.

Hem seams

The most common types of machine seam for finishing the edge of the product are a variety of seams in the hem. Let's start with the simplest - with an open edge. We take the product and iron its edges to the wrong side. After that, we sew with a regular or decorative stitch at a distance of 5-7 mm from the bend. If we are dealing with a crumbling fabric, then it is better to overlock it first. This type of seam is used so as not to weigh down the bottom of the product. But the edge is always prone to fraying.

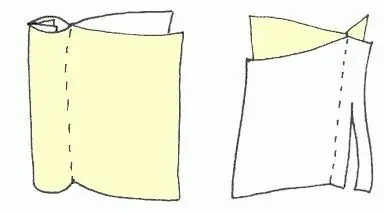

Double seam allows you to hide the raw edge inside. To do this, first iron the edge in the direction of the wrong side, and then bend it and iron it again, hiding the edgeinside. After that, sew the seam in such a way as to stitch both layers. Such a seam is more reliable, but also voluminous at the same time, which is not very good for light products.

Another option for the hem - a double seam is sewn twice, 2-3 millimeters from the bottom bend, and the same distance is retreated from the upper inner hem. This type of seam is found mainly in trousers and jeans, which are most subject to wear.

Rim seams

For the neckline and the bottom of the sleeves in blouses, sometimes a radically different technology is needed. Machine seams here should be light and with minimal scarring so as not to rub the skin. In such cases, edge seams are used.

It is quite difficult to make them without preliminary basting, because the seamstress has to follow three edges. In this case, the edging is bent inwards, which significantly complicates the process.

Kant is a flap of fabric that closes the outer edge of the product. It is selected so long that it is enough for finishing around the entire perimeter. On both sides, the edging flap is ironed in the direction of the wrong side. Then it is swept to the product and stitched as close to the edge as possible.

A slightly more complicated option is the pre-assembly of the edge of the product into folds. In such cases, edging is simply necessary in order to add durability to the product. But stitching it is much more difficult so that the folds are uniform.

Decorative seams

Sewing a product is not a problem. Muchit is more difficult to make it beautiful, graceful and fashionable. For these purposes, there are different types of machine seams. A decorative stitch chart is always included with your sewing machine. Their use will already significantly enliven the product. But you can resort to more professional methods. To do this, you need to show a little imagination and sewing skills.

In fact, all decorative and finishing seams are based on connecting and edge. It's just that in their performance, techniques that are not quite specific to them are used. Which ones, we will consider below.

Complicated fit

We all know that, for example, a blouse consists of two front shelves and a back. There is nothing particularly decorative about it. Pure classic and boring. But the same shelves can be cut out of two or more parts, and to connect them, use different types of machine seams, the schemes of which we examined above.

Add some "hooliganism" in the cuffs. We will sew them with an overhead seam, and even from several flaps. At the same time, the edges of the latter are slightly disheveled, as if they were small patches. Of course, such a technique will work only with natural fabric, which practically does not crumble. But it shows the main principle of finishing seams - do not be afraid to experiment.

Sewing machines

To perform the basic types of machine seams, a household sewing machine is enough. In addition, modern models often come with additional paws and nozzles that facilitate this process. Some of them even allow you to do small embroidery,which is important in the process of decorating products.

At the same time, some craftswomen say that no modern model can compare with classic Soviet cars. This indicates that for quality work, skill and a little professional intuition are enough.

Recommended:

Where is the French seam used? His technique of execution and a brief description of other types of seams

Probably, every girl in school at needlework lessons was taught the basic types of seams for hand and machine sewing. But over time, these skills disappear. And when it is required to apply knowledge in practice, it becomes an almost impossible task. Immediately you need to remember how to perform a French seam, how to tuck the fabric and re-master the art of threading the lower and upper threads in the machine. All fabric processing technologies are divided into two groups. It's easy to remember them

In what cases is a connecting column tied?

If you have already heard about such a concept as a connecting column, but do not know what it is about, then pay attention to this article. Here you will find information about its purpose and scope

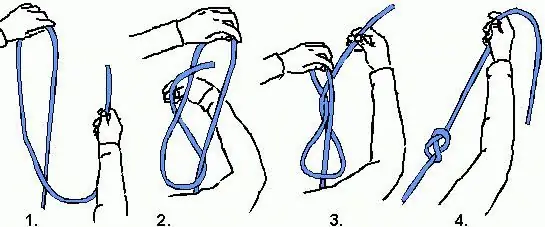

Variety of nodes: types, types, schemes and their application. What are the nodes? Knitting knots for dummies

Knots in the history of mankind appeared very early - the oldest known ones were found in Finland and date back to the Late Stone Age. With the development of civilization, knitting methods also developed: from simple to complex, with a division into types, types and areas of use. The largest category in terms of the number of variations is sea knots. Climbers and others borrowed them from her

Set of stitches for elastic edge: knitting needles and hook

On products for children and adults, it is often necessary to make the beginning of the canvas stretchy. To do this, there are special techniques for dialing loops for an elastic edge. Moreover, they are designed both for knitting needles and for a hook. Therefore, needlewomen with any knitting can choose a convenient technique

Jagged edge with knitting needles: knit slowly

When knitting any product with knitting needles, it is necessary not only to hide the ends of the threads, but also to decorate its edge beautifully. And here needlewomen turn to a variety of typesetting edge options. One of the most popular is the scalloped edge of the knitting needles