Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Our ancestors have been decorating the walls with wood inside and out since ancient times. Now eco-materials and eco-design are back in fashion. "Back to nature, but with all the benefits of civilization" - that's how the slogan sounds. A decorative wooden board just helps to cope with the task.

The benefits of wood finishes

- Wood is an environmentally friendly and natural product. Polished parquet floor, furniture, facing boards look beautiful. But unedged wood looks more natural.

- Wood cannot replace concrete or stone in terms of strength. Nevertheless, it has sufficient strength and wear resistance. In addition, the wood is quite flexible, and nothing will happen to it where, for example, aerated concrete breaks or plaster cracks.

- A house lined with wood is not only beautiful, but also functional. Wood has a low level of thermal conductivity. And your house will always be warm.

- The facade board, which is used to line the house from the outside, is quite elastic and porousmaterial, and it is a good sound insulator.

- Decorative wall boards come in a wide range of colors and can be matched to any design and decorated to your liking.

- Practically anyone who has hands and brains can assemble such a wooden cladding. There are only three types of fastening of a decorative board: tenon-groove, overlap and butt.

Disadvantages of wood finishes

- High cost. This is especially true for wood species such as oak. So, if you decide to put an oak parquet floor, it will cost you a pretty penny.

- Wood is flammable. It, of course, is impregnated with various flame retardants, but they only reduce flammability, and do not completely exclude it. It should be borne in mind that this is all chemistry.

- Periodic prophylaxis. This is especially true for finishing with unedged boards outside the house or facing rooms with high humidity. In these cases, the protective wood coating will need to be renewed every few years.

Types of processing

According to the type of board processing, there are edged, unedged, slab. It is worth deciding that a board in construction is usually called wooden products, in which the width of the plank exceeds its thickness by 2 or more times. Edged board is processed from all sides.

Processing is carried out by a technical method - planing, grinding, sawing. Unedged board is processed only from two sides. Slab or wane are sliceslogs around the edges. They have only one flat surface, the others are not processed.

Purpose of boards

According to the purpose, the boards are divided into frontal, terraced and ship boards. With a frontal board, you can finish the transition zone from the wall of the house to the roof. Sometimes this is the name of the material that is used to make platbands.

Ship board is designed, as the name suggests, for finishing the sides and decks of ships. This thick, strong, well-planed board of expensive wood has a luxurious look, texture, and is considered an expensive material.

Terrace board - the same as ship board. But not so expensive wood is used for its manufacture. Therefore, it will be cheaper to decorate a balcony or facade with a decking board than a ship one.

Types of finishing boards

The most popular material is lining. This name appeared at the beginning of the 20th century, when train cars began to be lined with material from the inside. Typically, the cladding is mounted on a frame made of wooden beams. There are many varieties of lining, and the most common are block house and imitation timber. With the appearance of the timber, everything is clear, and under the block house we mean planks that look like rounded logs. Now marketers are trying to separate the block house into a separate type, but this is a lining.

Planken is a decorative material. Planken appeared before modern lining. Initially, the wagons were lined with a flat board, and only a littlelater, a tenon-groove connection appeared on the boards. Interior trim with planken overlap or butt. And the outside is always mounted with an overlap. Moreover, the boards are packed horizontally so that rain flows down them. If you are going to mount planken boards end-to-end, keep in mind that you need to leave a match wide gap between the boards to compensate for the expansion of wood with fluctuations in humidity and temperature.

Now, not only the floor, but also the walls are covered with laminate. Laminate is an affordable alternative to parquet.

Tree species for finishing boards

The finishing board is most often made from linden, alder, oak, ash, aspen, larch, cedar, pine and spruce. Oak is an elite breed, it is distinguished by excellent strength. The price per square meter starts from $100. Linden or alder will be a budget option, prices for which range from $20-30 per square meter. Aspen and ash will be a little more expensive, the price per square meter - from 40-50 dollars. Larch is the very high-quality and durable ship board. Cedar is valued almost as much as larch, although it is less durable and resistant to decay.

What to focus on when finishing with a decorative board. Photo

And how to decorate the bedroom? Finishing with a decorative board will be appropriate at the head of the bed. It can be a small fragment or the entire wall.

A large plasma TV looks great against a wooden background. Guests will definitely appreciate the stylish interesting design.

In the kitchen, you can decorate a wall with a decorative board, which is adjacent to a wooden surface and / or a dining table. Or the whole wall.

How to make a decorative board with your own hands. Helpful Hints

Cedar, pine, aspen, oak, beech, birch are used for the manufacture of decorative cutting boards. Usually they are decorated with a pattern that is applied with acrylic paints or burned out. Such boards are not used for cutting. Most often they are used as an element of decor or as a tray. Stacked cutting boards, which are assembled from bars of different colors, also look very good. Cutting boards used as an element of decor can be different. For example, in the shape of a pear, apple, leaf, heart, etc. How can I make a decorative board myself?

To make a board you will need:

- wood blank of the shape you need;

- decoupage card;

- PVA or special decoupage glue;

- acrylic paints, including gold, silver, bronze;

- sponge;

- scissors;

- acrylic varnish;

- tassels;

- beads;

- ribbons.

Sand the wooden blank on both sides and cover with 1-2 layers of white primer. It can be white acrylic paint thinned 2 to 1 with water. Or it can be the acrylic primer itself. Cut out the desired pattern from the card and soak in water for 20 seconds. Remove from water, blot excessmoisture. Glue the picture to the workpiece. Drop glue on top and evenly distribute it with a brush. Dry 30-60 minutes. Take the paints and paint the places free from the picture as you like. You will create an interesting effect if you take a sponge, mix gold and bronze paint, dip the sponge into the mixture and apply paint around the edges and along the ends of the workpiece. Dry for 30-60 minutes. Then take the varnish, apply on the workpiece in an even layer. Dry. Cut 20 cm of ribbon, fold in half and tie a knot. Pass the ribbon through the hole in the workpiece so that the knot is at the front side. It is necessary to thread one loop into another, tighten and hide the knot at the back. It remains to put on a few beads and hang a decorative board on the wall or door.

Recommended:

How to decorate photo frames with your own hands: ideas, materials, recommendations. Photo frames on the wall

Standard wooden photo frames are the simplest solution for photo placement. Finding a frame design option suitable for an individual interior is quite difficult, so a home-made base will be the best solution. You can use already prepared. It is only important to decide how to decorate the photo frame with your own hands. For this, completely diverse tools and materials can be used

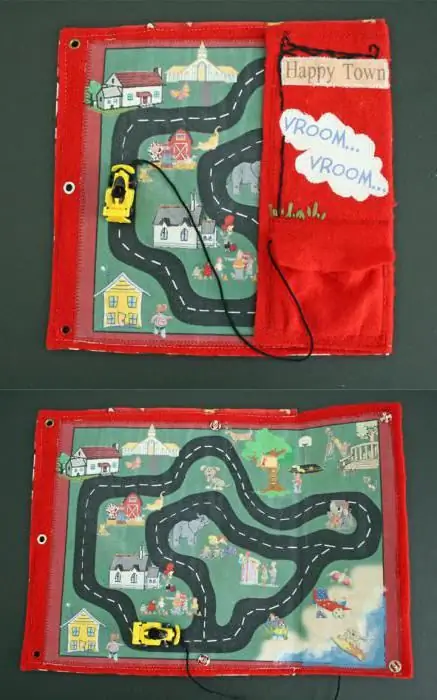

How to make DIY board games: ideas, instructions and photos

Board games are a great way to spend time with the whole family. You can make such entertainment easily and quickly from improvised materials. The handmade wooden game will be an original and memorable gift

Wood burning. Wood burning for beginners

Woodburning is an art that first appeared at the end of the last century in the capital of Russia. At first, this technique was used to make nesting dolls. Subsequently, this method of artistic processing of wood was called pyrography

DIY decorative paper: step by step instructions for making

Decorative paper is perfect for creating original postcards, packaging and gift envelopes, which is quite easy to make with your own hands. The process of its creation not only allows you to create something new and original, it also perfectly develops imagination

How to make a wall-mounted makiwara with your own hands

This article talks about what makiwara is, what types of makiwara are. And also presented several options for how makiwara is made with your own hands