Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:45.

- Last modified 2025-01-22 22:09.

When sewing products at home, you should pay attention to such an element as the neck, the processing of which is sometimes difficult for beginners. Let's look at the existing ways of processing cutouts of a garment and the technological operations necessary for this.

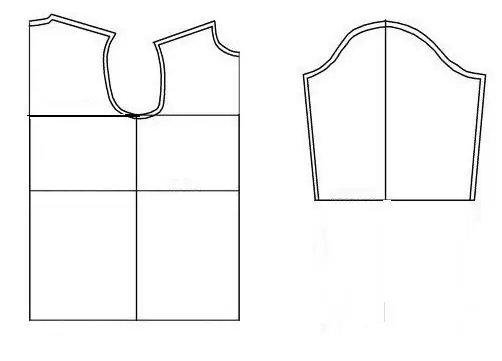

One of the classic options for such processing is turning cuts of armholes and necks using an oblique inlay or processing the neck with a facing, which is cut out from the same fabric with the obligatory location on it in such a way that the fractional threads of the parts and facings coincide with them. The exception is fabric embroidered with sequins, it is treated with lining fabric.

When cutting out facings around their entire perimeter, an allowance will be required. To prevent stretching of the sections, it is necessary to strengthen each detail of the facing with interlining. The liner piping, along with the seam allowance, must be ironed to the wrong side of the fabric piping, transferring the contours.

How to process a round neck

The processing of the neck of the product begins with the stitching together of the turning parts,ironing and overcasting seam allowances. Then its inner cut also needs to be overcast. Then we cut off the facing with the neck with the front sides inward and grind it. We cut the allowances of the resulting seam as close as possible to the line, in the places of rounding we make notches that do not reach the seam line by 2 mm.

Please note - if there is no need to stitch the neckline, the piping allowance should be ironed. At the same time, make sure that there are no small folds. It is most convenient to carry out the ironing operation on the edge of the ironing board or on a special pad.

Next step: stitch the stitching to the allowance near the stitching seam, turn it to the wrong side. The edge should be swept in such a way that the seam is located near the fold from the inside, and from the front side it would not be visible. You can also stitch the neckline - if desired.

Next steps

Piping is attached to the allowances of each shoulder seam with a couple of stitches. If the design includes a zipper, sew it in before you start to cleanly turn the neck.

The allowances of its short sections protruding beyond the edges of the cut should be unscrewed and sewn to the fabric braid of the zipper. In the case of an onboard product (or having a one-piece selection), the latter is first turned onto the front of the product, then the neck is already cut off with its facing. After that, the facing is cut until its short cut reaches the edge by 1 cm and stitched.

Then, in a similar way, the seam allowances are cut close to the line, the hem (or facing of the cut) along withturn the neckline with a turning inside out and baste, then iron and sew to each other.

A square-shaped neck or a V-shaped neckline is processed similarly to a round one. To turn the facing inside out, allow seams in the corners and at the top notch almost close to the seam.

Processing armholes

But attention is required not only the neck. Armhole processing is no less important. They are just as cleanly turned with turning, similar to a round neck. It is convenient to simultaneously perform side seams. This will allow you to adjust the product in width without tearing off the facing - due to the allowance of each side seam. It is important at the same time that the allowances of the facings and side seams of the product itself match in width.

How to achieve this? First, shoulder seams should be processed both on the product and on each facing with overcasting and ironing the allowances. Then - overcast the facings along the inner sections. Over the entire product (on both sides), the facing is chipped off with the armhole on the front sides and grinded off.

The seam allowances are cut very close to the notch stitching in the rounded areas and ironed over. Then it is stitched to the seam allowances next to the seam. One line is used to grind the facing with the side sections of the product. Overcast and iron seam allowances. The facing is turned inside out, the edge is swept out. Then it is sewn to the seam allowances (side and shoulder).

Howperform a single turning of armholes and necklines

This operation is performed for models without sleeves and with narrow shoulders - in this case, the facings of the armhole and neckline are a single piece. Since as a result of connecting all the circular sections, the turning is impossible, the shoulder seams are temporarily left open. They are ground down later.

First, the lower edges of the facings are overcast. They should be folded with cuts of the neck and armholes facing each other. Then chop off the cuts of the armholes and neckline with the alignment of the seam lines. Stitch, leaving about 3cm of seam unstitched below the marked shoulder line. Bartack along the edges of the seam.

The seam allowances are cut close to the stitching. The facing on the front is turned inside out, the front with the back and the facings are folded with their front sides. The front is pinned to the back along the marked shoulder line, stitched. Then the shoulder lines of the facings are chipped off and also grinded.

The allowances are ironed at the shoulder seams. Open sections of armholes and necks are chipped and grinded. The front is pulled out from each shoulder edge of the back, while the facing of the back is automatically turned inside out. The edges of the armholes and neckline are ironed from the side of the facings. The side cuts of the facings and the product itself are folded face to face and chipped off, then grinded in a single line.

If shoulder cuts are very narrow

With a width of shoulder sections of 3 cm or less, the facings are pinned to them face to face and stitchedexactly to the place of the shoulder seams, at the end of which a backtack is made. The seam allowances are also cut very close to the notched stitching in rounded areas.

The facings are turned to the side of the wrong side, ironed. Shoulder sections are ground with the front sides without tacking the facing. The seam allowances are laid out, the folded edges are butt-sewn with a few stitches.

Pure turning with bias tape

Another type of armhole or cutout processing is the processing of the neck with an oblique inlay, both finished and cut out of fabric. Ready-made inlay (made of cotton or other material) can be bought at any sewing store. They are matte or glossy, their range is quite wide. The recommended width of the finished inlay folded in half is 4 cm.

Processing the neckline with an inlay begins with its unfolding and ironing. If it is decided to cut it out of the main or lining fabric, the inlay blank is folded in half inside inside out, ironed to give the inlay the shape of a rounded cutout (this operation is called “pulling the edges”), open cuts fit.

The inlay and the neckline are pinned to each other with the front sides in such a position that the fold of the inlay is about one and a half centimeters from the planned seam line, and its open sections are on the allowance. The inlay is sewn from the inside of the back and front exactly along the line marked for the neck. Seam allowances are cut off.

The slanting inlay is turned to the wrong side, its edges are swept and ironed. Another shoulder seam is made, side seams are sewn down.slices. Attention should be paid to the even location of the cuts of the neck relative to each other. At the resulting seam, allowances are ironed out, overcast and manually sewn along the neckline. Neckline - optional.

How to handle corners

If the corners are internal, the bias trim is stitched to the corner. It turns to the side, the fold is fixed with a pin, the inlay is sewn from the corner, swept out and ironed. A fold is laid in the corner and sewn up. On the front side, the edge is detached.

When processing external corners, sew an oblique inlay to the corner, notch its inlay allowance next to the last stitch, then sew the inlay from the notch. In the corner, the allowance is notched obliquely. The inlay is swept on the wrong side, a fold is formed and sewn up in the corner. The edges are ironed and sewn away.

Extra Tips

To prevent distortion of the cuts of both the neck and armholes during the process of turning with an oblique inlay, iron the interlining from the inside.

Seaming the side cuts should be started after the armhole has been turned clean.

If the product does not have a fastener in the neck area, you should start by stitching the shoulder sections. Do not forget to iron and overcast the seam allowances.

Knitted neck processing

Knitwear is the unchanging leader among the fabrics from which women's clothing models are sewn. It produces the most elegant and elegant models. They are practical and comfortablecan be worn all year round.

Neck processing in knitwear plays an important role. There are many options here - finishing with a variety of elastic bands, a steering wheel from the front surface (we are talking about hand-knitted products in which the neck is processed with knitting needles), decorative edges, etc.

Let's consider the technology of processing the neck of a product made of elastic knitwear. For example, let it be the processing of the neck of the dress. Suppose our neck has the shape of a boat, we will process it by turning. The processing principle is the same for cutouts of any shape - oval, square, etc.

Where to start?

First of all, according to the figure, we specify the shape that our neck has. Its processing begins with folding the entire product in half and pinning with pins. We cut out the facing from a piece of fabric folded in half, attaching it to the neckline and circling the last one with chalk.

As you know, in knitwear, the neckline stretches more easily, so the facing is subject to gluing with a knitted doubler. If the jersey is thick enough, you can get by with regular non-woven fabric.

We grind the facing along the shoulder seams and pin or tack to the neck of the product. We lead the line at a distance of about 7 mm from the edge. The seam allowances are trimmed to 3-4 mm, notches are made on them for turning out. Fix the facing with a finishing seam along it at a distance of about 1 mm from the seam.

The bias trim option is only suitable for oval neckline.

So our neck is ready. Processing it, as you can see, is not such a difficult matter. Good luck to everyone in mastering the secrets of sewing!

Recommended:

Artistic leather processing: history, techniques and features

Leather is a natural, environmentally friendly material that is flexible in work. It is soft, pleasant to the touch, durable. Working with it allows you to show your creativity and create unique products from unnecessary, old things. In the article we will consider what is the artistic processing of the skin

The effect of an old photo: how to make vintage photos, the choice of a program for working with photos, the necessary photo editors, filters for processing

How to make the effect of an old photo in a picture? What it is? Why are vintage photos so popular? Basic principles of processing such photos. A selection of applications for smartphones and computers for retro image processing

Artistic processing of photos in Photoshop

In the age of modern technology, cameras also rise to the occasion. An abundance of lenses for different genres of shooting, filters and special lenses help to make a great shot almost on the first try. But even here there are those who want to improve even more. Thanks to this, various programs for artistic photo processing are very popular. Even a child knows the name of the most common of them. Of course, we are talking about Photoshop

How to sew a women's T-shirt: pattern and product processing

Sewing clothes is a very entertaining activity and a good way to save money on buying things. For example, a women's t-shirt. The pattern is very easy to build, the fabric requires a maximum of one and a half meters, the process will take only a couple of hours, and the product will come out several times cheaper than in the store

We sew takes: pattern, processing, choice of material

One has only to try to work on this piece of clothing, as it immediately becomes clear that it is not at all difficult to sew berets with your own hands. The patterns described in the article are very simple to perform. Even the most inexperienced seamstress will cope with such a task. A little diligence, and a fashionable new thing will be ready