Table of contents:

- Basic rules for threading the upper thread into a sewing machine

- Rules for threading the lower thread of the sewing machine

- Features of installing the bobbin in the vertical hook

- Features of installing the bobbin in the horizontal hook

- Features of overlock threading

- Threading needles

- Looper threading

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:45.

- Last modified 2025-01-22 22:09.

Usually household sewing equipment is quite easy to operate. But for a simple layman who uses a sewing machine once a year to restock kitchen towels or pillowcases, it is quite difficult to remember the basic rules for threading or winding a bobbin. However, a few minutes in the study of the instruction manual - and you can get to work. But how to thread a sewing machine if this document is lost? Or how to deal with a three-thread or four-thread overlock if the threading scheme is completely forgotten? Are there any ground rules? This is what will be discussed next. So how do you thread a sewing machine?

It's worth noting that top threading and bottom threading will be required for sewing, so it's a good idea to look at both processes in more detail and understand the principle.

Basic rules for threading the upper thread into a sewing machine

Of course, all models have their differences, but the principle of operation of these units is the same, so we can distinguishground rules:

- The thread must be on a spool, which is installed on a special pin. Depending on the model of the machine, this can be a pin on the top panel of the machine body or a specially equipped case for a skein, located near the handle for carrying the machine.

- Following the thread must pass through the holder, providing the desired tension and tension control area.

- The next element is the thread lift lever. If the thread is not threaded through it correctly, it will tangle on the fabric and break.

- Threading the sewing machine involves passing it through special clips and hooks that provide the necessary tension and prevent tangling. Therefore, the thread, having descended to the needle from the feed lever, must necessarily pass through the hooks on the holder.

- When entering the hole of the needle, you need to make sure that the thread does not wrap around it, and there are no corners on the edge that make it difficult to pass. Some higher-end models have a special device for inserting thread into a sewing machine. However, it is quite easy to do without it.

Rules for threading the lower thread of the sewing machine

The principle of machine stitching is that two threads are involved in the work, which are intertwined at the puncture site. But on how to thread the thread into the machine, all its work depends. After all, most of the malfunctions are reduced precisely to improper operation. Therefore, for the correct operation of the unit is requiredcorrect top and bottom threading of the sewing machine. The whole process of setting the bobbin thread can be divided into two steps:

- winding the bobbin;

- setting the thread in the hook.

Almost all new models have special indicators on the body for winding the bobbin (a small spool with a lower thread), but if there are none for any reason, you should examine the body of the unit. It should have a small pin with a switch and a winding limiter in the form of a disk on the pin.

Then it remains to figure out how to thread the bobbin. To do this, the coil is installed on the main pin (or in the box), passed through the holder device for tension, attached to the coil with several turns, switched to the winding mode and the unit is started. This mode is usually activated by moving the bobbin pin to the side.

Next, you need to insert the thread into the sewing machine. And here you should determine the type of shuttle, on which further actions depend.

Features of installing the bobbin in the vertical hook

The vertical shuttle is characterized primarily by its structure and location. It usually has a removable housing where the bobbin is inserted. The free edge of the thread should be passed into a special hole for the pressure plate. This is done quite simply, just put the thread in the slot and pull. Next, the body is inserted into the shuttle device until it clicks. In this case, the so-called finger should look up, and hold the partfollows a special clamping handle. When the bottom thread is in place, the needle is lowered and both edges of the threads (top and bottom) are brought to the working surface. This is probably all you need to know about how to thread a sewing machine.

Features of installing the bobbin in the horizontal hook

The process of threading the lower thread of the machine always starts with winding it on the bobbin. Installing a thread in a horizontal shuttle is more primitive, like its device as a whole. Here the bobbin is placed in a special hole under the cover under the working needle. Then the free edge of the thread is drawn by pulling it into special slots. Next, lower the needle and bring out both edges of the working threads.

The quality of the stitch depends on how to thread the sewing machine. Ideally, the threads should intertwine in the puncture of the fabric, but if loops form on one of the sides, you should make sure that the tension is adjusted. If the problem persists, check all elements of the filling path again.

Features of overlock threading

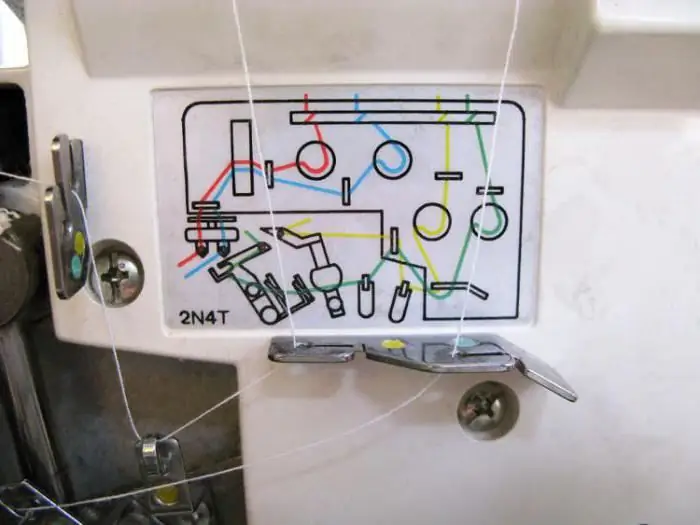

All leading manufacturers of sewing equipment, taking care of the user, put marks-pointers directly on the body for threading working threads and paint hooks. Each serial number has its own color: red, green, blue or yellow. But how to thread into an overlock without pointers?

Here you also need to understand the basic principle of the unit. For example, in a four-thread overlock, the first two threadsdesigned for needles, the rest - for the upper and lower loopers. So how do you thread a two-needle overlocker?

Threading needles

All spools should be installed on special pins and the threads should be passed through the holes on a special lifting rack. Then, on the upper part of the body, thread it into the holes in front of the clamping devices for tension, designed to prevent tangling of the threads during the operation of the unit. Further, each of them has its own separate path from the tension regulator to the exit to the needle or looper. In a two-needle overlock, both threads are connected in the area of the lift lever and pass through all the hooks together, separating only at the entrance to the needle. The thread from the first spool on the pin goes to the first needle, the second to the other. Next, you should deal with the threading of the loopers, which, in fact, overcast the edge of the products.

Looper threading

The third pin is the upper looper. The thread descending from the clamping device along a special groove must be led out to the panel with holders (hooks). Clinging to one of them, she is taken to the upper looper. Then they fix it in the holder again and pass it through the hole of the large hook.

The fourth pin is the lower looper. The thread is also lowered to the panel with the holder, attached to it, then the overlock flywheel is scrolled so as to open the looper stand, the thread is caught on two hooks and passed into the looper hole. Then press the foot of the unit to start work. The first few stitches should be made with the flywheel, andthen you can add speed.

If you know the basics of sewing devices, none of the models will cause difficulties with the question of how to thread a sewing machine and overlock. Everything is quite simple. The main thing is just to study all the elements of the unit and pay attention to the refueling process.

Recommended:

How to fill the sewing machine before work

Not every needlewoman knows how to handle a sewing machine. This article will be of interest to those who use such a convenient device for the first time in their lives. The biggest difficulty comes when trying to thread. If there are any problems with the upper thread, then you will have to tinker a little with the lower one. So, how to fill the sewing machine?

How to insert a needle into a sewing machine: instructions for use, operation and repair, tips

Needle device. Types of sewing machines. Instructions on how to insert a needle into a sewing machine. How to insert a twin needle into a sewing machine. Tips for operation. Incorrect needle installation: the cause of the breakdown

Why does the sewing machine break the thread: the main causes and how to fix them

Why does the sewing machine break the thread? Main reasons: defective needle, incorrect thread tension, incorrectly inserted tension regulator spring, notches on machine parts, incorrectly selected material

Selection of needles for sewing machines for various purposes. How to insert a needle into a sewing machine?

The fundamental condition for the proper operation of the sewing machine - for high-quality stitching and perfectly sewn things - is the correct installation of the needle. Many needlewomen are wondering how to properly insert a needle into an old-style sewing machine ("Singer" or "Seagull"), how to do this in the case of a new machine. In order to answer this question, you need to understand the principle of installing a needle

Machine seams: technology and types. Machine seams: connecting, edge

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible