Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:35.

- Last modified 2025-01-22 22:09.

Not every needlewoman knows how to handle a sewing machine. This article will be of interest to those who use such a convenient device for the first time in their lives. The biggest difficulty comes when trying to thread. If there are no special problems with the upper thread, then you will have to tinker a little with the lower thread. So how do you thread your sewing machine?

Upper Threading Technology

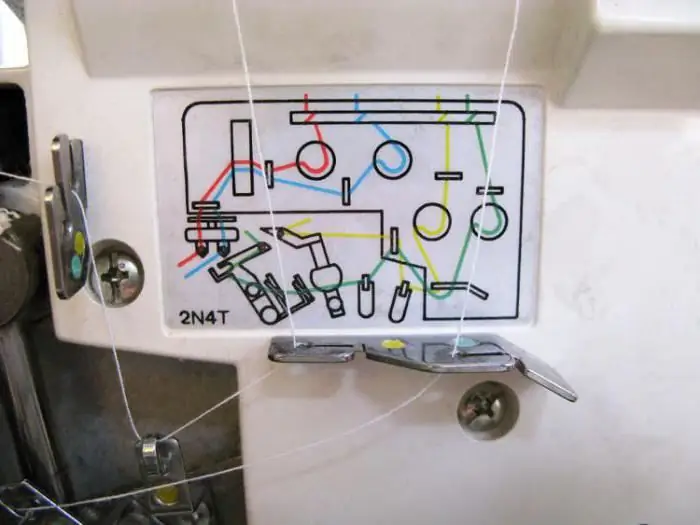

This part of the job shouldn't be too difficult. You can insert the thread correctly, simply guided by intuition. In addition, most machines have a schematic representation of this process on the body.

To properly thread your sewing machine, it is recommended that you follow these instructions:

- The thread from the spool must be passed through the mount on the body.

- Then, the thread is threaded into a special regulator that tensions the threads, and then the thread must be brought into a compensation spring similar tohook.

- The next step is threading into the thread guide, after which the end must be passed through several fasteners before threading into the eye of the needle.

- The thread should be guided from the side where there is a notch or groove running along the needle (any of these elements are easy to feel for your fingers).

To understand how to properly thread a sewing machine, you need to know that some models are equipped with a fork that acts as a thread guide. In this case, you just need to put the thread on it, without passing it through the hole. However, this type of machine is quite rare.

How to thread the lower thread

Before you start threading, you need to figure out a little where the thread should be threaded and where it will be located.

Unlike the upper thread, the lower thread is wound on a bobbin, and not on the usual spool. For this part there is a special cap where the bobbin should be inserted. The thread is threaded under the spring plate.

The cap provides a certain thread tension, depending on the model of the sewing machine.

Correct threading of the bobbin

Now it's time to talk about how to thread a sewing machine, namely the bobbin thread.

Here you need to remove the additional table from the typewriter by moving it to the left. Initially, the shuttle plate is removed. To raise the needle to its highest position, turn the handwheel. To remove the bobbin mechanism, it must be gently pulled by the edge and thentake out the bobbin.

When threading a sewing machine, the thread is wound onto a bobbin by attaching the spool to the top peg and connecting it to the thread holder in a crosswise position. At this point, its edge should go to the flywheel. The bobbin is mounted on the second pin, the thread is attached, wrapping around the body several times. Then, pressing the pedal or turning the handwheel will thread the bobbin.

How to install the bobbin

To understand how to properly thread a sewing machine, you need to know this little thing. The thread should unwind only clockwise, the end is threaded into the bobbin mechanism through a special hole. It remains only to return the part to the shuttle and move the tongue to the position in which it was previously, i.e., simply lower it. This position fixes the mechanism motionless.

After filling is carried out, the mechanism must be installed at the bottom of the machine, following the instructions attached to the unit.

What you need to know about thread tension

It will be useful to get acquainted with this part of the article before proceeding directly to work. Having figured out how to thread the sewing machine, it's worth talking about thread tension.

The tension is adjusted using a special bolt located on the bobbin case by turning it.

When unscrewing the bolt, it is recommended to remember: in order to avoid breakage, it is not unscrewed more than half a turn.

The tension itself is neededadjust according to the density of the material to be sewn, its structure and the upper thread tension.

What you need to know about caring for your sewing machine

Like any other mechanism, the machine needs some maintenance, which prolongs its life. There is nothing difficult here:

- The internal parts are systematically lubricated using special oil, it is recommended to do this procedure once every six months.

- Threads and needles are selected depending on the type of fabric.

- Internal parts should be cleaned regularly with a special brush.

- If it is carried out, sewing fur, woolen or knitwear, then all the above actions should be carried out more often.

Recommended:

How to thread a sewing machine and an overlocker?

Usually household sewing equipment is quite easy to operate. But for a simple layman who uses a sewing machine once a year to restock kitchen towels or pillowcases, it is quite difficult to remember the basic rules for threading or winding a bobbin

Selection of needles for sewing machines for various purposes. How to insert a needle into a sewing machine?

The fundamental condition for the proper operation of the sewing machine - for high-quality stitching and perfectly sewn things - is the correct installation of the needle. Many needlewomen are wondering how to properly insert a needle into an old-style sewing machine ("Singer" or "Seagull"), how to do this in the case of a new machine. In order to answer this question, you need to understand the principle of installing a needle

Tips for beginners: how to work with polymer clay. Required materials and tools, work technique

One of the popular materials for creativity is polymer clay. Jewelry, souvenirs, toys, etc. are created from it. To master the technique of working with polymer clay, you need to consider the advice of experienced craftsmen. There are many subtleties and nuances, knowledge of which will allow you to avoid serious mistakes. Next, consider which masters give advice to beginners and how to work with polymer clay

Wood engraving with a laser machine: features, benefits, materials for work

Laser engraving on wood allows you to turn the raw materials familiar to everyone into something beautiful and elegant, without making any special physical effort. For the woodworking industry, this technology turned out to be a breakthrough, opening up many opportunities for creating unusual artwork. Now craftsmen do not have to worry about how to apply narrow intricate patterns on wooden furniture or cut a decorative blank from plywood

Machine seams: technology and types. Machine seams: connecting, edge

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible