Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Every woman wants to look special. This applies to makeup, hair, and clothing. Nowadays, not everyone can afford to buy a thing that will be unique. Therefore, many women sew clothes for themselves. The sewing machine is the first assistant in this matter.

Beginner seamstresses often face the problem of thread breakage at the time of sewing. Don't panic. This is easy to fix on your own. More on this later in the article. First you need to find out why the sewing machine breaks the thread, top or bottom, and how to deal with it.

Why is this happening?

There are many reasons. Let's consider the main ones. After all, it is not always possible to call the master. Especially if the work is urgent and there is no time to wait.

Thread tension

The most common reason why the sewing machine breaks the thread (lower or upper) is too much tension. The interlacing of threads in this case occurs on the fabric. To fix such a problem is quite simple - just loosen the tension.

KA weak tension also leads to a break in the thread. The threads begin to get tangled in the shuttle, which is why they break. This flaw also affects the beauty of the seams.

Needle

Another reason why the sewing machine breaks the thread is the needle if it is not set correctly. When it touches the walls of the hole in the needle plate, the thread will begin to cling to its irregularities, which will lead to a break. In such a situation, the needle will break and the thread will break.

Regulator spring

The thread can also break due to the fact that the spring is incorrectly set in the voltage regulator. First, there should be large coils of the spring closer to the body of the machine. Secondly, it is necessary that the spring in the regulator axis moves easily. If the tension adjuster is not assembled correctly, this will be the main reason why the manual sewing machine breaks the thread.

The machine will not work properly if the needle is not properly installed in it. It should be inserted all the way, and the nose of the shuttle should pass next to its recess.

Other reasons

Also, notches on the machine parts can also file and tear the thread. To eliminate such malfunctions, you should go through them with a needle file.

The problem may also be hidden in the bobbin case. A heavily tightened part leads to a break in the thread. Difficulties also arise if the cap is clogged with threads and dirt.

Most often the reason why the thread breaks is due to incorrectly installed elements. In this case, the machine will not pick up the thread correctly, whichwill cause it to break.

Poor lubrication can also cause the sewing machine to break thread. To prevent this from happening, just lubricate the working parts.

If the presser foot pressure is too strong, sewing speed and quality may be affected. On some models of sewing machines, there are three modes that correspond to the type of fabric: light fabric, thick and embroidery mode. Choose the one that suits the material used.

Why does the sewing machine break the upper thread? Wrong materials selected

The thread in the machine can break not only because the parts are installed incorrectly, but also if the material for sewing was chosen incorrectly. When difficulties are associated with this factor, correcting the situation is quite simple. You just need to replace the fabric with a more suitable one.

We continue to consider the question, because of which the thread breaks and gets confused in the typewriter:

- When using threads from old stocks, you should pay attention to their quality. Very often threads with knots made of cotton material will break. Threads that are too thick should also not be used.

- An incorrectly selected needle can cause the thread to break. These tools are selected depending on the thickness of the fabric. Otherwise, the hinges will turn out sloppy, and the finished product will look untidy.

- Defective needle. Check needle point and eye before sewing.

- Wrong bobbin size. If it is too small or too large, the thread will not wind around it properly while sewing, causing it to break.

As you can see, there is nothing complicated. To fix a broken thread, you just need to carefully check everything and immediately fix the problem.

Winds the thread in the machine

It often happens that the thread in the machine does not break, but simply winds. Sewing clothes in this case is also impossible. After all, the parts of the pattern cannot be fastened together with seams.

The reason may be the same as when the thread breaks. Therefore, in this situation, you must first check the thread tension, then make sure that there is a spring in the tension regulator. If everything is checked and corrected, but the stitching is still looping, then the problem may be that the lower and upper threads are of different thickness. It is very important that both threads are of the same number.

Another reason why the line loops may be washers not clamped in the tensioner. If this is the case, then you should disassemble this part of the device and check all its parts for rust and dirt. If everything is done correctly, then the machine will start working properly.

If the machine malfunctions, you should not immediately contact the master, most likely, it is simply assembled incorrectly. After checking each of the options described above and making sure of the quality of the materials, the seamstress, having found the cause, can easily eliminate it on her own. If he cannot do this, then it is better to invite an adjuster.

If a woman wants to look beautiful and go out in beautiful clothes, she should get a sewing machine and learn how to use it. Using her most daring decisions and imagination, she can become irresistible, elegant and especially feminine.

Recommended:

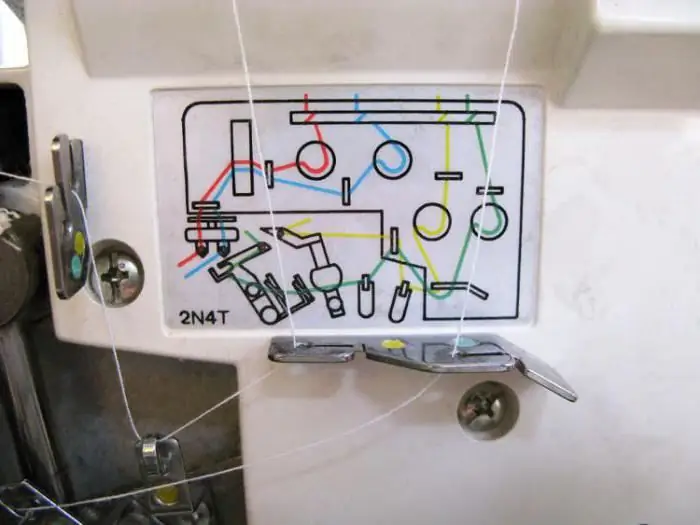

How to thread a sewing machine and an overlocker?

Usually household sewing equipment is quite easy to operate. But for a simple layman who uses a sewing machine once a year to restock kitchen towels or pillowcases, it is quite difficult to remember the basic rules for threading or winding a bobbin

How to insert a needle into a sewing machine: instructions for use, operation and repair, tips

Needle device. Types of sewing machines. Instructions on how to insert a needle into a sewing machine. How to insert a twin needle into a sewing machine. Tips for operation. Incorrect needle installation: the cause of the breakdown

Selection of needles for sewing machines for various purposes. How to insert a needle into a sewing machine?

The fundamental condition for the proper operation of the sewing machine - for high-quality stitching and perfectly sewn things - is the correct installation of the needle. Many needlewomen are wondering how to properly insert a needle into an old-style sewing machine ("Singer" or "Seagull"), how to do this in the case of a new machine. In order to answer this question, you need to understand the principle of installing a needle

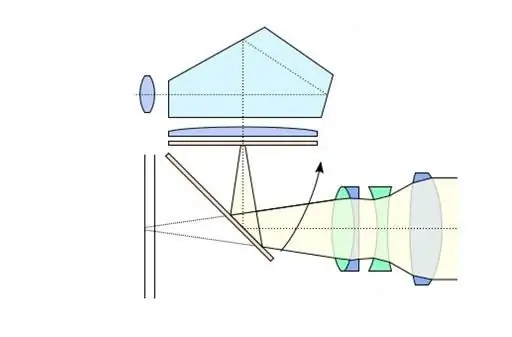

What is the difference between a SLR camera and a digital camera and why is this question posed incorrectly?

In the article we will talk about what is the characteristic feature of digital and analog SLR cameras

Machine seams: technology and types. Machine seams: connecting, edge

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible