Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Beginner needlewomen often wonder how to properly insert a needle into an old or new sewing machine. After all, the thread immediately breaks if it is incorrectly installed, stitches are skipped, or the device abruptly simply stops sewing. Here are some tips to help you avoid these problems.

Needle device

The simplest and most ingenious invention is the machine needle. Of course, compared to manual it is more difficult. But if one day you understand its device, then the question of how to insert a needle into a sewing machine will never arise again.

The device of the needle does not depend on what type of machine - mechanical or electric. All machine needles have one design:

- rod or blade;

- flask thickened;

- point;

- ear;

- long and short grooves;

- flat.

Varieties of sewing machines

All sewing machines can be divided into two groups: household and industrial. Everything is much better with householdeasier. In these machines, the needle is often already inserted. And if you still have to replace it, then there will be no question of how to insert a needle into a household sewing machine, since the place in it for the tool is made specifically according to its shape, that is, it is inserted in one and only way.

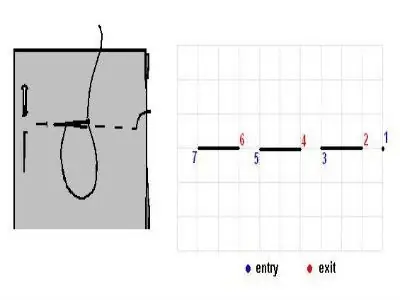

The situation is somewhat more complicated with industrial sewing machines, because if the needle is not inserted correctly, the unit simply will not work. Inserting thread in most industrial machines must be done from left to right. But it is also known that the thread is inserted from the side of the long one, and exits from the side of the short groove. That is, during the installation of the needle, it is necessary to pay attention to the fact that the long groove looks to the left, and the short one to the right (exactly the opposite happens in a household machine).

Instructions on how to insert a needle into a sewing machine

- First you need to carefully study the attached instructions for the sewing machine. If you have a good idea of \u200b\u200bhow the apparatus and the sewing process are arranged, there will be no question of how to insert a needle into a sewing machine. You just need to strictly adhere to the manufacturer's requirements.

- It is necessary to pay attention to the fact that the sewing machine can be adjusted to a certain standard of needles. If you use a non-standard tool, it will break.

- According to the thickness, it is necessary to check the conformity of the new needle and thread. To do this, the tool is taken with a long groove up, the thread is placed in the groove and the surface of the blade is probed. The thread should completely fill the groove, but overdo not protrude if this protrusion has formed - a too thin needle for the working thread has been selected.

- If you managed to find a suitable needle, this is not the time to insert it into the needle bar: you should put the tool on a glass surface and raise it to eye level. If the rod is evenly spaced along the entire length, then such a needle can be used - it is not a curve.

- The nail plate must be drawn along the needle, it is necessary to start from the flask. This determines whether the tip of the needle is blunt or not. If so, then you cannot use such a tool.

- Finally, the right needle is inserted into the sewing machine. Do not forget that the long groove when threading into the needle bar always looks in the direction of the thread. To install the needle into the machine, it is necessary to raise the needle bar to the upper position and loosen the needle holder screw, so the groove into which the needle is installed will be visible. The flat is attached to the bottom of the groove, the needle through the needle holder should go into the needle bar. It is inserted all the way, and then securely fixed with a fixing screw.

Setting the twin needle

Many novice seamstresses are also wondering how to insert a double needle into a sewing machine. The answer to this question is very simple: any sewing machine that sews a zigzag stitch can be equipped with a twin needle. The main thing to pay attention to before buying it is the width of the gap of the needle plate and the distance between the tools.

However, in thissewing machine, like "Podolskaya", you won't be able to insert a double needle. Indeed, in such machines, there is only one round hole in the needle plate, and in order to use a double needle, you will need a wide and narrow gap, which is also necessary in order to perform a zigzag stitch. In addition, one more spool rack and additional thread guides are required.

If you plan to insert a needle (double) into a sewing machine such as "Seagull", you should pay attention to how it enters the hole in the needle plate when performing a straight stitch. The tool must pass exactly in the center of the hole. If there is a misalignment, it may break.

User Tips

There are a few tips to help you less likely to encounter the problem of replacing a needle in a sewing machine due to breakage. These tips are:

- never pull the working fabric out from under the presser foot towards you;

- you can not help the working machine by manually pushing the fabric;

- make sure that the needle plate is always attached firmly;

- The foot should only be attached after the needle has been lowered;

- if you have to put a line across a thick seam, do it carefully and not at fast speeds;

- If the upper thread breaks, the sewing machine skips stitches, and the sewing machine makes a lot of noise during operation, you need to replace the needle.

Half of the problems are due to improper care of the sewing machine. Therefore, one morean important reason why the machine breaks the thread, skips, etc., is unlubricated parts. Therefore, in order to avoid problems, it is worthwhile to lubricate each part of the mechanism in time.

Incorrect needle setting: cause of breakage

Problems are caused by a tool that has been installed incorrectly. These malfunctions, in turn, make it impossible to continue the sewing process. The main faults are broken needles and skipped stitches.

The causes of machine needle breakage include:

- mismatch between needle number and fabric thickness;

- tool distortion;

- needle not fully inserted into needle bar;

- the needle bar itself may be bent.

Skip stitches

The reasons for skipping stitches when changing the needle are as follows:

- needle bent;

- point dull;

- there is rust on the tool;

- needle inserted wrong side;

- needle does not match device type or fabric thickness.

The operation of the device can be adversely affected by simple manipulations to install the needle. If there are problems with the tool or for some reason it is necessary to repair the components of the sewing machine, it is best not to engage in amateur activities, but to contact the service department for the repair and diagnostics of such units.

Recommended:

Selection of needles for sewing machines for various purposes. How to insert a needle into a sewing machine?

The fundamental condition for the proper operation of the sewing machine - for high-quality stitching and perfectly sewn things - is the correct installation of the needle. Many needlewomen are wondering how to properly insert a needle into an old-style sewing machine ("Singer" or "Seagull"), how to do this in the case of a new machine. In order to answer this question, you need to understand the principle of installing a needle

Texture paste: types, composition, instructions for use, purpose and use

Modern technologies allow craftsmen and needlewomen to open up new possibilities and horizons in creativity when creating their works. In recent years, many new techniques have arisen, old types of applied art have been developed

Sewing machine PMZ (Podolsky Mechanical Plant named after Kalinin): description, care instructions

Sewing machines of the Podolsk Mechanical Plant have been produced since 1952. The lineup over the past years is represented by a wide variety of cars. There are both manual and foot operated options

Stitch "needle forward" in embroidery. Embroidery "forward with a needle" with diagrams and photos

Simple and versatile are the seams, during which the movement of the needle is directed forward. They can be used for manual work when sewing clothes or soft toys, decorating finished products, or as auxiliary techniques

Machine seams: technology and types. Machine seams: connecting, edge

Sewing clothes by hand is no longer profitable. With the help of a sewing machine, this happens faster and better. And different types of machine seams allow you to make the product as durable as possible