Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:35.

- Last modified 2025-01-22 22:09.

Wood products, especially those that are exposed to the external atmosphere and located on the street, need protection from the influence of water, sun and other factors harmful to wood. To extend the life of a wooden product, improve its decorative properties, special protective compounds are used - wood stains.

Stains are water-soluble (water-soluble) and non-aqueous, in which the pigment is dissolved using various chemical mixtures.

Basic Features

Non-aqueous protective coating formulations are characterized by increased moisture resistance.

As with the water-soluble mixture, non-aqueous stain is used:

- to protect wood from decay;

- for mold resistance;

- to protect wooden products from pests and microorganisms.

After drying, it forms a protective film on the surface that is not washed off with water, and the surface itself, if the mixture is properly applied, does not require additional painting with varnish.

This stain cannot be diluted with water. Pigment blend deeppenetrates the wood fibers and does not cause it to swell.

The disadvantage of almost all non-aqueous stains is a pungent odor, so the composition should be applied to a wooden base in a well-ventilated area, in a respirator.

Important! The work requires care so that dust does not settle on the sticky surface, drops or smudges do not form.

Types and composition of non-aqueous pigment mixtures

Protective coatings have different characteristics in their composition.

Non-aqueous stain for wood has such components that affect the technical features and the qualitative composition of the mixture.

Main types of non-aqueous solutions by chemical composition:

- Alcoholic - a solution of aniline dyes in alcohol, characterized by rapid drying (25-30 min.). The liquid structure of the alcohol stain causes the rapid penetration of coloring pigments into the layers of wood. However, the fluid consistency of the composition does not allow it to be applied to the surfaces to be painted with a brush or roller; noticeable spots and stains may remain. It is recommended to use an airbrush (sprayer) when applying this type of wood stain to the wood surface. Perfectly proven when finishing an impressive area of wooden surfaces.

- Oil formulation, typically based on linseed oil, ideal for achieving UV resistant finishes. It can also be used for decorative purposes in the processing of wood. The mixture is produced with a large rangecolors, perfectly masks the imperfections of wood. Can be applied to the surface with any available tool: sponge, brush, foam roller, spray gun. To dilute the non-aqueous oil stain, white spirit must be used. Oil-stained finish takes two to four hours to dry, depending on indoor or outdoor temperature and concentration.

- Wax stains are mainly used to mask small defects in wooden surfaces. In terms of their composition, wax and acrylic mixtures are similar to oil ones, but they have much greater moisture resistance. However, such a composition is quite sensitive to abrasion or any other mechanical stress, therefore it is suitable for covering minor surfaces. Widely used in restoration work. Drying time for wax and acrylic stains is about five hours.

Staining technique

Before applying a protective coating, the surface of the wood must be treated in a special way.

Basic rules for stain application:

- Wood is treated with sandpaper to remove any bumps, scratches or dents from the surface. This is a rough sanding.

- Begin grinding with a sandpaper with a grain size of 80-100, finishing with an abrasive sandpaper with a grain size of 150-180. In this case, processing is always carried out along the wood fibers.

- Minimum coverage - two layers, after applying the first, polish the surface of the finishsandpaper.

- If there are stains on the wood, they are removed by sanding before painting.

Tools and methods for applying stain:

- Oil, acrylic and wax stains are applied to the surface of the wood with a natural bristle brush, you can use a swab of a material with a smooth structure.

- A spray gun is used for alcohol stains.

- Aqueous and acrylic mixture coating is applied with a swab, roller, synthetic brush.

Coating methods:

- Accepted method - application of a protective composition is carried out in excess without subsequent wiping. In this way, deep saturated tones are achieved. It is possible to partially wipe off the excess after the previous layer has dried. Suitable for oil, wax and acrylic stains.

- The second method is to apply with excess and wipe off excess tampons. It is applied to the surface of the wood in a circular motion with the removal of smudges and stains until the layer dries. Applicable for water and acrylic formulations.

Naqueous stain: colors

Manufacturers produce several options for filling protective mixtures.

These are the following types:

- Transparent stains. Used to create a protective film on the surface of wood. In addition, transparent mixtures perfectly shade the structure of the tree, give the product a well-groomed look, tint and protect.

- Color compositions. This type of stain can be used for design purposes, to give the treeunusual shades, and turn ordinary pine into bog oak.

Non-standard, bright color shades are also produced: emerald, pearl, various tones of the now fashionable gray color in design.

The palette of shades is quite diverse, with imitation of valuable wood species. Manufacturers produce colored stains for oak, ebony, rosewood, walnut, mahogany, wenge and others.

Different points of view

Stains differ mainly in their composition and consistency. The difference is visible when comparing some species with each other.

For example:

- Non-aqueous stain “Oak” contains organic solvents, synthetic resins and dyes. It is resistant to abrasion, has fire retardant properties, and is used to give wood noble shades. It is possible to cover in one layer with a brush or roller, as the mixture penetrates deep into the structure of the tree. Customer reviews confirm the decorative properties of this type of stain, especially dark colors.

- Non-aqueous stain “Lacra” is weather resistant. It contains organic solvents, synthetic resins, plasticizers, pigments. Lacra dries quickly, applied in 2-3 layers to obtain the desired shade. The coating is carried out with an airbrush, swab, synthetic brush. According to consumer reviews, the Lacra wood stain really does not cause swelling of the wood, it is easy to apply with a spray gun, but it has a very pungent odor. Recommendation: paint in a ventilated area,before work, clean the wood from dirt and dust.

Which is better: there's no arguing about tastes

What composition to choose to protect or decorate wood - the consumer decides. The main thing is to correctly apply the selected type of non-aqueous stain.

In this case, it is necessary to take into account the general rules or subtleties of applying to the surface of a wooden product, adopted for all compositions of stains:

- before use, the stain can be heated, this will enhance the absorption of the composition into the wood structure;

- so that there are no drips, do not dip the brush or roller heavily in the composition, it is recommended to take a small amount of solution;

- surface after grinding should be treated with white spirit before applying a protective coating;

- make a test on the surface to understand the effect of the selected stain on the treated wood.

And everything will definitely work out!

Recommended:

The book "Modeling the Future" by Gibert Vitaly: review, reviews and reviews

People want not only to know, but also to be able to change their future. Someone dreams of big money, someone of great love. The winner of the eleventh "Battle of Psychics", mystic and esoteric Vitaly Gibert, is sure that the future can not only be foreseen, but also modeled, making it the way you want. He told about all this in one of his books

"Alize Baby Vul": reviews of needlewomen, composition, colors

In knitting, one of the problems is the right choice of yarn. Especially carefully approach this issue when knitting for children. One of the materials suitable for this is Alize Baby Wool yarn. Reviews about her are mostly very laudatory. However, in order to finally decide whether the material is suitable for knitting the intended products, it is necessary to carefully study its characteristics

Paul Gallico, "Thomasina": book summary, reviews and reader reviews

P. Gallico is the author of both children's and adult books. His works are not only remembered by readers with an exciting narrative, but also suggest reflections on faith, love and kindness. One of these works is Paul Gallico's story "Thomasina", a summary of which can be found in this article

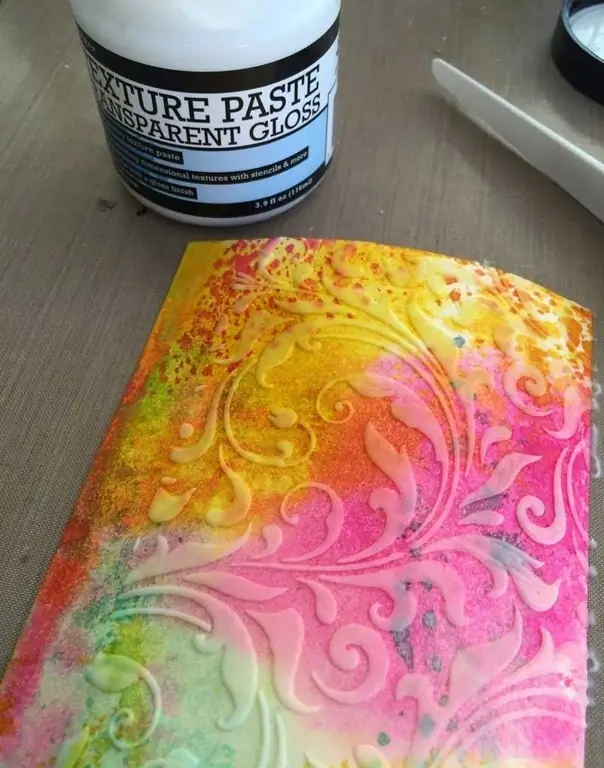

Texture paste: types, composition, instructions for use, purpose and use

Modern technologies allow craftsmen and needlewomen to open up new possibilities and horizons in creativity when creating their works. In recent years, many new techniques have arisen, old types of applied art have been developed

Polymer clay varnish: types of varnish, classification by glossiness, rating of the best varnish, rules of use and reviews of masters

What is polymer clay? Why varnish it? What are the types of varnish and how to apply them correctly? You can find answers to these questions, as well as information about prices and brands of varnishes in this article. A lot of useful information for beginner needlewomen, as well as tips on avoiding basic mistakes when working with polymer clay. Interesting facts and comparisons: this and much more is presented below