Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

This article will focus on auxiliary sewing material that is used to create clothes. With its help, the most vulnerable to deformation parts of clothing, such as shoulder seams and neck, are processed, thereby maintaining their original appearance.

Where is it used?

There is a common belief that formband interlining is one of the specific types of fabric. However, this is not so, it is not even a kind of ordinary interlining. This is just a piece of ordinary adhesive interlining, cut for convenience in the form of an oblique inlay with a width of 1.2 cm. At a distance of 0.4 cm from the edge, there is a chain seam necessary to stabilize the shape of the product.

Most often it is used in the area of the neck, collar or shoulder seam. If you want to knit the neck of a sweater or sew the details of the product at an angle of 45 degrees, then the non-woven formband, the photo of which is below, is perfect for this. It is able to securely fix the shape of the product, soft in contact with the skin and, importantly, does not allow the fabric to lose elasticity.

There are a large number of color shades, from gray to pure white, but most often you can find white on saleand graphite color. The material is sold by the meter in specialized stores.

History of occurrence

The use of formband non-woven fabric began in the 19th century. This idea originated in factories in Germany, when it was necessary to find a cheap and easy-to-use lining material for the production of clothes. In fact, non-woven formband is not even a fabric, since a paper-like canvas is used for its production.

People often call it a fabric, perhaps because of little awareness, or maybe because it is actively used in sewing fabric products. Most often it is used during embroidery with beads and a cross.

As for Russia, it began to be used in factories only at the end of the 20s, and for hand-made things only 16 years ago.

Features and properties of the material

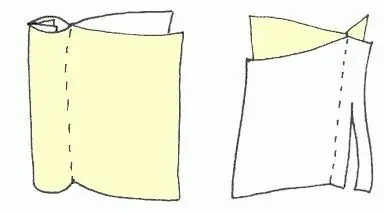

This is a unique material that can be both on a regular basis and on an adhesive one. But no matter what is taken as the basis, the non-woven formband is always elastic, very thin and able to quickly restore its original shape. In its production, ordinary interlining is used, which is cut into strips of a certain width. Since it is most often used on the corners of the product, these strips must be cut obliquely. Needlewomen often ask the question that if it is impossible to find interlining formband, how to replace it? You can take an ordinary interlining and cut strips of the required width from it at an angle.

Himselfinterlining is made from specific fibers that have undergone a certain chemical treatment. Do not underestimate the non-woven formband, because it is very thin, but it is able to protect the product from twisting, shedding and deformation. The value of this auxiliary material lies in the fact that it is able to increase the technical characteristics of the main material that makes up the product.

The main feature that the material has is its strength. It has been experimentally proven that products sewn with its use are more resistant to wear and abrasion. Formband protects them from high humidity and dirt. Very often this material can be found on sequins and when embroidering with beads and ribbons. In such products, the ability to maintain shape is the main quality of non-woven fabric.

A very important feature of water-soluble interlining is its sensitivity to high temperatures. If you iron a product for which interlining was used, then its parts will stick together.

Scope of application

The scope of non-woven formband is quite extensive.

- When tailoring. Interlining is used in the manufacture of both outerwear and delicate thin dresses.

- Production of various pieces of clothing. Most often this applies to the neck of the product. Adhesive-based interlining is used to finish the edges of a fabric or a certain product. Thanks to additional protection, the shelves, shoulder seams, necks, and other parts of knitted clothing that are most often exposed to stress retain theiroriginal appearance and not subject to wear.

- For creativity. The needlewomen also took note of the interlining. Most often it is used for embroidery with threads, beads, sequins, ribbons. Thanks to him, the threads will lay down evenly and beautifully, without creating tension and "accordion". If we are talking about beads, then you definitely cannot do without interlining.

- For compositions. For florists, this material for use in boutonnieres and bouquets is also in the first place, well, except for the flowers themselves. The interlining, lined with individual fibers on a bouquet in the form of a cobweb, looks especially beautiful.

Use

In order for the product to retain its shape, you need to know how to properly iron the non-woven formband to it. To do this, it is necessary to cut out the non-woven fabric of the same size as the fabric part, making allowances for the seams. We slightly heat the iron, iron it to the fabric from the wrong side. This must be done carefully and dry. So that the interlining does not move out, it is best to first glue it in several places, only then fully heat it up. When the parts are stuck together, they must be set aside for a while to cool.

Material care

If the interlining is in a skein, then it must be stored in a place protected from sunlight and with a relatively constant temperature. If it is part of floral compositions, then you should also avoid contact with water, as the interlining will lose its shape.

But not a single warning applies to interlining, whichused to make a piece of clothing, as it is protected by a layer of fabric.

Recommended:

What can be done from new and used cartridges

For various reasons, cartridge cases can accumulate in the house, either spent (after firing), or new and unused. Previously, they could be massively collected in quarries. Today they are also not difficult to get, and some have had them for several years and it’s even impossible to remember where they came from, but it’s a pity to throw them away

What is a symmetric coin and where is it used

Description of the functionality and scope of the term "symmetric coin". Examples of its use in probability theory are given, as well as a paradox of probability theory is described and situations where a symmetrical coin is used in life are given

How the "cat" application is used by creative people

It turns out that the application "cat" can be used in an extremely diverse way. And not only kids can do their work in this technique. If you use a creative approach, then the “cat” application will help decorate life around and bring new colors to it

What is shutter speed? In what cases is this function used and is it needed in the camera?

The camera is a device with many functions and features. Depending on the combinations of these parameters, a radically different result is achieved even when shooting the same object. To begin with, it is worth knowing what shutter speed is, when it is needed and what effect can be achieved with it

Where is the French seam used? His technique of execution and a brief description of other types of seams

Probably, every girl in school at needlework lessons was taught the basic types of seams for hand and machine sewing. But over time, these skills disappear. And when it is required to apply knowledge in practice, it becomes an almost impossible task. Immediately you need to remember how to perform a French seam, how to tuck the fabric and re-master the art of threading the lower and upper threads in the machine. All fabric processing technologies are divided into two groups. It's easy to remember them