Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Today, many types of threads are used in the textile industry. In the process of home needlework, various varieties of such materials are also used. They differ in many characteristics. There is a huge selection of threads for sewing, knitting, embroidery, etc. In order not to get confused in this variety, you need to consider the features of each variety. This will allow you to make the right choice. The main types of threads and their features will be discussed below.

General definition

Today there is a huge number of all kinds of threads (the photo is presented below). They are called in professional language twisted products. They can be indefinitely long. Flexible textiles, which are threads by definition, are spun from individual fibers.

Sewing, embroidery and knitting products can be created from natural or synthetic materials. Without threads, it would be impossible to sew clothes, create fabrics. They are used both in industrial production and in needlework. Threads can either be the final product or be subjected tofurther processing.

Depending on the application, there are several types of threads. If you need to connect the individual parts of shoes, clothing and other similar products, sewing twisted products are used. If you want to finish fabrics, loop cords are needed. For knitting, a separate type of thread is also produced. Hand and machine embroidery is created from floss.

Considering the types of threads and their purpose, it should be noted that this indicator largely depends on the characteristics of their production. This is influenced by the type of fibers, weight, number of additions and the type of weave. Fineness also affects the properties of the threads. This is a measure of the cross-section of the fibers of linen, cotton and other types of materials.

Threads vary in cross-sectional size. The thicker the thread and the denser the fibers are folded in it, the stronger the cord will be. This indicator is also largely influenced by the type of material from which the yarn is made.

Threads are dyed in a variety of colors during processing. Their range is extremely wide. Moreover, threads of various shades are produced for embroidery. This is necessary to create a quality product. Technical threads, which are used, for example, for sewing bags, can be of the same color. In all cases, depending on the area of application, the color fastness index is important. The higher it is, the better and more expensive the thread.

Sewing threads

What are the types of threads? There are a great many of them. The most common type is sewing thread. They are produced in the vast majoritycases of cotton yarn. Less commonly, flax fibers are used for these purposes. Natural silk threads are highly valued all over the world. Their cost is very high. Synthetic products are much cheaper. It can be kapron, lavsan, etc.

Sewing threads are used everywhere. Therefore, this is the most common variety. Certain requirements are put forward for such products. They must have high strength. Such threads do not break under a certain load. Also their surface is smooth.

Sewing threads are made from combed yarn. It is folded several times. Further, the material is subjected to double twist (right or left). Cords made by the presented method from natural fibers lend themselves well to bleaching. They also absorb paint without losing their color for a long time. Therefore, the range of colors of these products is large. During the production process, the surface of the thread is given a matte or glossy structure.

There are different types of fabrics and threads of the presented type. They are produced in accordance with GOST. Their tone is determined by the color map installed at the factory.

Sewing threads can be first or second grade. This indicator is determined in production. To do this, an employee of the company inspects one hundred packages of products of 200 m. Next, the appearance of the products is assessed, the presence of defects is determined, as well as the unevenness of the cord. White threads of the first grade should not receive more than forty-five negative marks. White, black and coloredthreads of the second grade can score a maximum of one hundred and ten remarks.

If the threads on the spool are characterized by a length of more than 200 m, then more marks are allowed. When evaluating the quality of threads, a specialist takes into account many nuances. Therefore, such work is carried out only by qualified personnel.

Varieties of sewing type threads

There are different types of sewing thread. They differ not only in variety. Threads of different lengths can be wound on spools. This figure can be 200-400 m.

There are several varieties of brands of sewing threads. They differ in the number of additions. Marks "prima", "extra" are made of threads in 3 additions. They are often used in mending and tailoring. These threads are of medium strength.

There are other varieties. So, the “special” brand is created from individual threads in six additions. They are more tear resistant. Such threads are often used in industry. For works for which special requirements are put forward, the brand "especially strong" is made. They can be folded nine or twelve.

Thread fineness is indicated by a number. The higher it is, the thinner the thread. So, for creating products from dense fabrics (for example, tarpaulins), cords No. 10 and 20 are suitable. These are very dense, thick varieties of products. For sewing outerwear, threads No. 30 or 40 are used, and for light dresses, blouses - No. 50.

All types of sewing threads are tested in production. Their extensibility and strength are evaluated. They depend on the quality and type of the originalraw materials, features of twist, as well as indicators of unevenness. In sewing varieties of threads, the strength characteristics reach 80%. These indicators are set by the standards for each brand. The greater the number of folds, the stronger the thread should be. These indicators are tested in production. There are tolerances. However, they should not go beyond the established standards.

Darning and embroidery threads

There is such a variety of threads as darning. They are made from cotton, blended yarn, as well as wool. Darning threads are made by loosely twisting 4 threads. For this, carded or cotton yarn is used. These threads are produced in skeins or balls. Thickness is also indicated by a number. The higher the number, the thinner the thread.

In industrial production and handicrafts, various types of embroidery threads are often used. They differ from sewing special structure. It can be glossy and matte. At the same time, there are much more shades and halftones for such products than for sewing threads. They also make high demands on the uniformity of the threads.

Products designed for embroidery are of medium strength. However, deviations and defects in their structure should be minimal. Such threads should easily pass through the fabric or canvas. Even if several threads are used at once, they should not be confused, twisted into knots.

The surface of the threads can be either glossy or matte. The first option is morepreferred. These types of embroidery threads are more expensive. However, the embroidery is elegant, silky. It has a uniform shiny structure. Therefore, glossy threads that undergo special processing are valued more than matte varieties.

Thread thickness may vary. They are sold in skeins or balls. For hand embroidery, threads with medium strength are used. In the course of work, the master does not exert significant physical effort to create a drawing. Therefore, thread breaks are unlikely. For machine embroidery, products with a high strength index are purchased. This is due to the peculiarities of the process of creating embroidery in this way.

Varieties of embroidery type threads

There are different types of thread. Mouline thread is one of the most popular materials for embroidery. It is believed that in this category these are the highest quality products. They are characterized by weak twist. Threads are soft. They are made from combed fine yarn. Muline is made from cotton, which undergoes additional processing. This operation is called mercerization.

Such processing allows you to remove pile from the surface of the threads. The result is a smooth product. Mercerization is a complex technological process. It increases the cost of threads. They are more expensive than sewing varieties. However, the pattern created with floss looks exquisite. These types of threads resemble silk or synthetics in their appearance.

Mercerization allows you to create shiny threads. They become stronger and softer. To Work withsuch a product is simple. The threads do not tangle, create a smooth structure on the surface. Depending on the embroidery technique, you can create a surface with a pattern of different filling density. The brightness of the color of the threads has been appreciated by private and industrial consumers. Muline receives many positive reviews. The thread does not tangle and is evenly distributed on the surface when passing through the canvas or fabric. It will not fade in the sun.

Mouline thread is produced in skeins of 10 and 20 m. A feature of the material is the fact that it can be easily divided into 6 threads. Thanks to this feature, you can create different patterns. If you want to make it thinner, separate 2-3 threads from a common ball. For embroidery, you can use a whole thread of 6 individual products.

The second type of embroidery thread is a single-twist cotton thread. It is twisted into 4 additions. This variety is called embroidery paper. Its surface can be shiny or matte. In the first case, the processing process includes a mercerization stage.

Embroidery techniques

There are a huge number of types of embroidery floss. Stitches can be very different. They can consist of different stitches, loops. This allows you to create different images and plots on fabric or canvas.

One of the most interesting is the cross stitch technique. In this case, the drawing consists of small squares. The more shades there are in the picture, the more spectacular it looks. Mouline threads allow you to combine different colors into separate halftones and shades. Crosses can be small and large. Most often, embroidery is created on canvas.

The larger the crosses, the more threads you will need to take to work. If they are very small, stitches of 2-3 threads are enough. If the cross is medium or large, it is better to take 4-6 threads. In this case, the surface will be monolithic. The canvas will not show through under the threads.

Considering the types of embroidery with floss threads, it is also worth paying attention to the technique of creating a satin stitch pattern. It is the brilliant texture of the threads that allows you to create bright, interesting images. Drawings created on the fabric will allow you to decorate any clothes, textile products. In this case, several threads for one stitch are also selected. They are evenly distributed over the surface.

Floss is valued for its ability to imitate the look of natural silk. Embroidery in this case looks very impressive.

Knitting threads

There are different types of knitting threads. They are used for machine or hand work. They can be both very fluffy and smooth. Threads are made from wool, synthetics and their mixtures. The last option is the most popular today. Such threads are relatively inexpensive. At the same time they are soft, durable and beautiful. The most common combination is acrylic and wool.

Thread colors may vary. Most often, one-color varieties are found on sale. In the process of knitting, they are combined in accordance with the selected pattern. However, there are also colorfulthreads. There are 2 brands in this category. The first of these is the melange variety. It consists of several threads of different colors. The second is a sectional dyeing brand. It consists of gaps of thread of a certain length, which are dyed in different colors.

There are certain requirements for different types of threads. When making stamps intended for knitting or crocheting, it is acceptable that products from different batches differ slightly in shade. The run should not be large. However, it is worth considering that it is worth buying threads for knitting with a margin. If there were not enough of them during the work, a new batch of threads may differ markedly in shade. And this is normal in this case. Therefore, it is recommended to purchase threads with a margin.

Threads of different thicknesses are on sale. They can be either very thin or thick. The choice depends on the type of product, as well as the tool. If you plan to knit with knitting needles, you need to attach them to the thread. If the yarn is ordinary, the tool should be 1 or even 1.5 mm thicker. For a bulky, downy thread, this figure is 2-3 mm.

If you plan to crochet, you need to throw a loop on it. It should be at the level of the tip of the tool beard. Often the size of the thread corresponding to a particular type of knitting needle is indicated on the packaging of the material. However, some manufacturers may neglect this requirement.

Varieties of knitting threads

Knitting threads are made from cotton, silk, synthetic and wool yarn. It is treated in a special way. ATthe result is different types of thread for crochet and knitting.

Iris, crochet, garus and other popular varieties of materials are made from cotton yarn. The first of these options is the most famous knitting material. Iris is made by twisting threads in 2 additions. The yarn for this is mercerized. It is quite dense, but does not curl easily.

Croche is made from both mercerized and plain yarns. 4 additions are made from it and double twisting is used. The thread has a weave that looks like a cord. Crochet is released in balls. They are measured in grams (10 and 20 g).

Also, wool is used to create knitting threads. It can be thick or thin. From natural fibers, angora, merino, crossbred wool and other varieties are used. To add additional decorativeness, they add metallized threads. The length in the skein is determined by the thickness of the product. Synthetic fibers can be added to the composition of the yarn. These include kapron, lavsan, akon, comelan.

Natural fibers

There are various types of woolen threads. One popular option is alpaca (llama) wool. It is lightweight, durable. Often this wool is mixed with other fibers. Pure alpaca is quite expensive. The coat is quite long. It does not roll down, it has high thermoregulating qualities. Naphthalene should not be used when storing alpaca wool products. For this, only natural moth repellers (lavender,cedar).

Angora wool is very pleasant to the touch. It is obtained from rabbit fluff. The wool is very soft and warm. It is durable and very fluffy. However, the disadvantage of the material is the fact that the fluff is not fixed firmly in the yarn. Angora is combined with other fibers.

Cashmere gets a lot of positive feedback. This yarn is made from the down of mountain goats. If it is used in its pure form, wool can roll. Therefore, it is used in combination with other fibers. Cashmere products are very pleasant to the touch. They are soft (better than silk), warm and very light.

Merino wool is harvested from a special breed of sheep. It has a high cost. The coat is long and white in color. She is resilient and warm. It is often used to create children's things.

Artificial yarn

One of the most common types of artificial type of thread is viscose. It is made from cellulose fibers. It is pleasant to the touch, hygroscopic material. When washing, things with the addition of such fibers should not be twisted. They require careful handling.

Another popular option is synthetic acrylic. It has many names. These are, for example, polyamine, PAN fibers. It is produced from natural gas. The fiber is added to other types of yarn. In this case, they can be used for knitting machines.

For greater elasticity, nylon or lycra can be added to the yarn. Synthetic materials are cheaper than natural ones. Therefore, they are often combined to improve the quality of the yarn and reduce itscost.

Having considered the main types of threads and their characteristics, you can make the right choice for this or that type of work. A huge selection of products is used in the textile industry and private consumers.

Recommended:

Sewing accessories box: types, description with photo, purpose and ease of use

A box for sewing accessories can become an indispensable tool for a needlewoman. You can make an organizer from improvised materials in a few hours. You can optimally organize the interior space

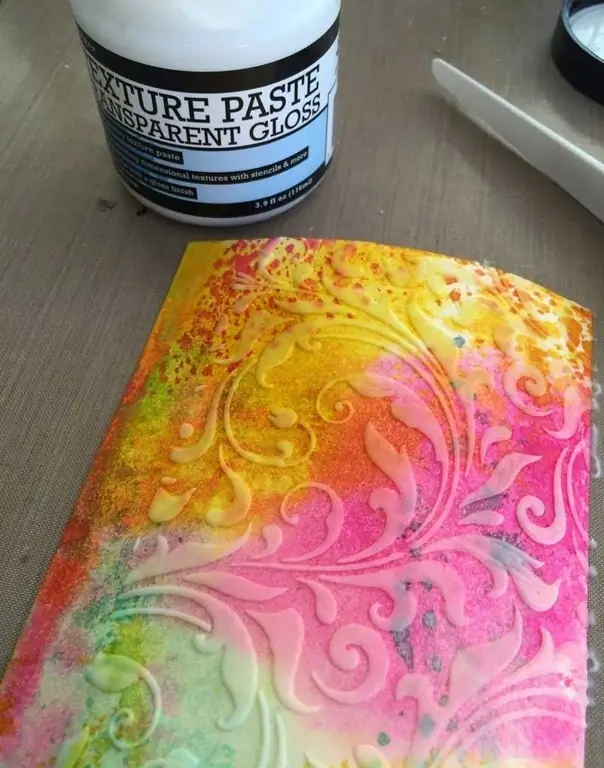

Texture paste: types, composition, instructions for use, purpose and use

Modern technologies allow craftsmen and needlewomen to open up new possibilities and horizons in creativity when creating their works. In recent years, many new techniques have arisen, old types of applied art have been developed

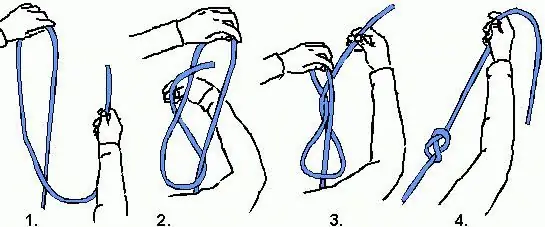

Variety of nodes: types, types, schemes and their application. What are the nodes? Knitting knots for dummies

Knots in the history of mankind appeared very early - the oldest known ones were found in Finland and date back to the Late Stone Age. With the development of civilization, knitting methods also developed: from simple to complex, with a division into types, types and areas of use. The largest category in terms of the number of variations is sea knots. Climbers and others borrowed them from her

Types of threads for knitting: overview, selection rules, advantages and disadvantages

It is difficult for beginner knitters to understand the variety of materials for needlework. About what types of threads for knitting are, what they are made of and how they are marked on the packaging, we will discuss in this material

Types of yarn for crocheting and knitting, their advantages and disadvantages

Many novice knitters (and maybe knitters) often have no idea at all about the huge variety of yarn. When choosing a material for their products, they are guided only by their own feelings. Accordingly, unpleasant consequences are detected, if not during work, then at the stage of wearing it is necessary. Therefore, it does not interfere with the beginning of the knitting path to get acquainted with the types of yarn at least a little