Inhaltsverzeichnis:

- Autor Sierra Becker [email protected].

- Public 2024-02-26 04:44.

- Zuletzt bearbeitet 2025-01-22 22:11.

Für viele Näherinnen ist es kein Problem, ein gestricktes T-Shirt oder eine Jogginghose zu nähen. Aber wenn es um komplexere Arbeiten geht, zum Beispiel um ein Hemd zu schneidern, müssen Sie entweder Erfahrung oder einen ziemlich guten Überblick über die Theorie der Verarbeitung dieses Produkts haben. Rückenpasse, Schulternähte, Knopflöcher und Stehkragen sind meist kein Problem. Doch die Verarbeitung des Ärmelaufschlags wird für viele zum Stolperstein.

Die Besonderheit des Longsleeves ist, dass es einen Schlitz oder, wie es auch genannt wird, einen Schlitz hat. Und wenn die kurze Version einfach hochgesteckt und angepasst wird, dann muss die lange Version sorgfältiger gearbeitet werden. Es gibt mehrere Verarbeitungsmethoden. Sie werden weiter besprochen.

Verarbeitungsoptionen

Die Ärmelbündchen eines Damenhemdes können mit einem klassischen und falschen Schlitz, einem sauberen Schnitt, einer Luftschlaufe und einem Reißverschluss verziert werden.

Ein klassischer Schlitz wird normalerweise in einem Herrenhemd verwendet. Nur manchmal machen sie einen Reißverschluss und einen rein bearbeiteten Schnitt aus. Auch wenn die Ärmelmanschette unter Manschettenknöpfen liegt, wird bei Hemden für Herren ein Schlitz gemacht und in der Mitte des Schnitts platziertTaste.

Lage des Ärmelschlitzes

Je nach Schnitt kann der Langarm ein- und zweinaht sein. Sowohl bei der ersten als auch bei der zweiten Version wird an der Manschette ein Einschnitt vorgenommen. Bei einem Ärmel mit zwei Nähten ist alles einfach: Die Abschnitte der zusätzlichen Naht, die 10-12 cm von unten entfernt sind, bleiben offen. Wenn der Ärmel eine Naht ist, wird er entlang der Abschnitte gef altet. Als nächstes wird die Mitte des unteren Schnitts bestimmt und die Senkrechte davon um 10-12 cm angehoben.

Beim Nähen von Kurzarmhemden nicht zuschneiden.

Option eins: Klassischer Spielautomat

Wir sind es gewohnt, mindestens drei Knöpfe an den Ärmeln eines Oberhemdes zu haben. Zwei am Bündchen (zur Weitenregulierung) und eine in der Mitte mit speziellem Schnitt. Ein solcher Verschluss wird normalerweise bei der Verarbeitung eines Schnitts mit einem klassischen Schlitz hergestellt. In diesem Fall fallen die Ränder des Ärmelbündchens mit den Rändern der Schlitze zusammen und bilden eine Überlappung. Als Zugabe für den Verschluss dient immer die Kante, die näher an der Naht des Ärmels liegt. Darauf wird der Button platziert.

Wie näht man eine Manschette an einen Ärmel mit einem klassischen Schlitz? Zuerst werden zwei Stoffstreifen entlang des gemeinsamen Fadens geschnitten:

- doppelt so breit wie der fertige Keder und 5 cm länger als der Zuschnitt;

- 1,5 cm breit und 0,5 cm länger als der Schnitt.

Ein großer Streifen wird verwendet, um die äußere Kante des Schnitts zu dekorieren, ein kleinerer wird verwendet, um die Kante der inneren Überlappung zu dekorieren.

- Die Bearbeitung des Ärmelbodens beginnt damit, dass sie einen kleineren Belegstreifen nehmen und ihn mit dem Schnitt des Ärmels verbinden, der näher an der Hauptnaht liegt. DafürDer Streifen wird von innen an der Schnittkante angelegt und angepasst. Danach wird die freie Kante über das Gesicht gestülpt und eine Linie gelegt, die die freien Abschnitte schließt.

- Nach dem gleichen Prinzip wird ein großer Streifen genäht, sodass die Bahnen im Besatz geschlossen sind.

- Am oberen Ende des Schnitts des Ärmels zu den Verkleidungen sind schräge Kerben angebracht.

- Der kleinere Besatz wird auf links gewendet und gebügelt, wobei die Kanten der Schnitte nach innen gebogen werden.

- Der große Besatz wird abgewickelt, die oberen Teile werden mit einem Umschlag umgeschlagen und entlang der Kante genäht, wodurch die obere Basis des Ärmelschnitts befestigt wird.

Bei der Schnittführung werden die bereits durch Einlage stabilisierten und miteinander verbundenen Manschettenteile am unteren Rand befestigt. Gleichzeitig wird der Stoff des Ärmels in F alten gelegt und tritt vom Schnitt an der Seite des Teils zurück, wobei die Schlitze oben entlang verlaufen, 3-4 cm.

Die Schlitze des linken und rechten Ärmels sind spiegelverkehrt verarbeitet.

Zweite Variante: Drehschnitt

Eine der einfachsten Möglichkeiten, einen Schnitt beim Nähen von Hemden zu verarbeiten, ist das Verzieren mit einem schrägen Besatz. In der Regel wird bei dieser Verarbeitung der Knopf nicht in der Schnittmitte angenäht.

- aus dem Hauptstoff "entlang der Schräge" einen Stoffstreifen ausschneiden;

- Ärmelzuschnitt gerade auseinanderf alten und Einlage Schnitt-an-Schnitt auf der linken Seite anbringen;

- der genähte Teil wird geglättet, über das Gesicht gef altet und eine Linie entlang der F alte gelegt.

Dritte Option: ein sauberer Schnitt

Für die Dekoration mit dieser Methode benötigen Sie einen Stoffstreifen in der gleichen LängeÄrmelschlitz plus 4 cm und Weite 4 cm.

- Der Artikel wird so auf die Ärmelleiste gelegt, dass sein Schnitt genau in der Mitte des Streifens liegt.

- Eine Linie wird um den Schnitt gelegt, Kerben werden in die Ecken gemacht und das genähte Teil wird von innen nach außen gewickelt.

- Das Teil wird ausgebügelt, die Kanten nach innen gesteckt und eine Linie entlang der F alte gelegt.

Diese Ausrüstung wird am häufigsten bei Damenhemden verwendet. Außerdem kann die Länge der Hülse hier beliebig sein, und Luftschlaufen aus dem Geflecht können in die Verkleidung eingeführt werden. Mit dieser Art der Schnittverarbeitung kann ein regelmäßiges Revers von innen nach außen gest altet werden.

Diese Methode wird auch bei Ärmeln mit Reißverschluss verwendet. Zuerst wird ein Reißverschluss angebracht, darüber eine Verkleidung. So entsteht ein ordentlich gest altetes Schloss.

Option vier: Fake-Slot

Der einfachste und schnellste Weg, einen Ärmelschlitz zu machen, ist, einen falschen Schlitz zu machen. Die Länge der Hülse mit diesem Design kann beliebig sein. In der Regel wird diese Methode beim Nähen von Damenbekleidung angewendet. Als Manschette wird ein Stoffstreifen verwendet, der der erforderlichen Länge entlang des Armumfangs entspricht + Überlappung am Verschluss. Am Ärmel wird kein Einschnitt vorgenommen, und die F alte wird nicht im Bündchendetail geschlossen. Die Ärmelblende, die nicht in der Manschette entlang des unteren Schnitts enth alten ist, wird zweimal umgestülpt und vernäht, und an der Manschette wird ein Knopf angenäht und eine Schlaufe angenäht.

Fünfte Option: Manschettendesign mit doppelter Naht

Wenn nach der Vorstellung des Modells der Ärmel zweinäht sein soll, dann wird der Besatz des Ärmels geschnittenganz machen. Das vereinfacht die Verarbeitung etwas, da Sie den Stoff nur noch richtig legen und nähen müssen.

Empfohlen:

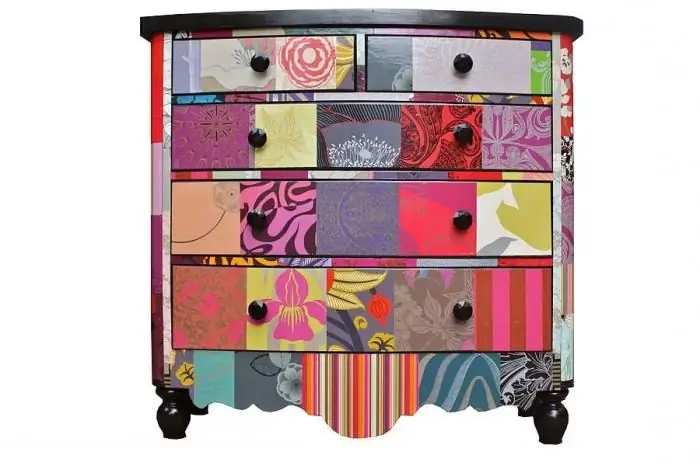

Patchwork. Ideen für den Urlaub und den Alltag

Verschiedene Produkte im Patchwork-Stil helfen, den Raum zu dekorieren. Ideen zum Dekorieren von Möbeln und Wänden sind sehr interessant. Zum Beispiel werden schön ausgewählte mehrfarbige Patches, die auf Schubladen und Möbelfronten geklebt werden, in einem Kinderzimmer blühen

Wie man ein Gummibandarmband auf einem Webstuhl webt? Von den einfachsten bis zu den komplexesten

Kleine Gummibänder werden immer mehr zur Grundlage für Schmuck aller Art. Es ist einfach, verschiedene Techniken zu beherrschen. Es reicht aus, die Grundtechniken zu verstehen - und bald wird es möglich sein, einem Anfänger selbstständig zu erklären, wie man ein Armband aus Gummibändern auf einem Webstuhl oder ohne Webstuhl webt

Arten von Ärmeln in der Kleidung

Wenn du selbst nähst, dann musst du nicht den Kanonen jeder Minute der Modetrends folgen. In diesem Fall können Sie eine Vielzahl von Musteroptionen verwenden und so immer mehr neue Kleidungsstücke erstellen

Dank an Großvater für den Sieg: Bewerbungen für den Tag des Sieges

Victory Day ist eine große Feier der Erinnerung daran, wie der Krieg beendet wurde und alles und jeden auf seinem Weg zerstörte. Bewerbungen zum Tag des Sieges sollten keinen militärischen Charakter haben, sondern im Gegenteil das Ende des Krieges zum Ausdruck bringen. Die Hauptsymbole des Sieges sind vor allem das St.-Georgs-Band, weiße Tauben und die Hauptattribute der Erinnerung sind die ewige Flamme und die Nelken. Und der rote Stern ist ein Symbol der Armee, die einen großen Sieg errungen hat

Lustiges Kostüm für den 1. April. Lustige Klamotten für den 1. April

Das menschliche Leben war schon immer voller Stress, also erfanden die Menschen Feiertage für sich selbst, um herumzualbern und Spaß zu haben, und so nervöse Spannungen abzubauen und Depressionen zu vermeiden. Zuallererst gehört dazu der Aprilscherz oder, wie er in unserem Land allgemein genannt wird, der 1. April. Dieser Feiertag wird von Zeichnungen und Partys begleitet. Damit es ein Erfolg wird, benötigen Sie für den 1. April ein Kostüm, das Sie selbst herstellen können