Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:45.

- Last modified 2025-01-22 22:09.

Some people have a strange but very remarkable and colorful hobby. It is called assembling ship models from wood. What does it take to make such a beautiful thing. It is not so easy to create a model of a sailing ship made of wood. From this article you will learn how to create a ship model from wood with your own hands. And we will also make a short digression into history.

Francis Drake

Many history buffs know the name "Iron Pirate" Francis Drake, his homeland was England. He became the captain of a sailing ship at only the age of 16. At first he was a ship's priest, and then a simple sailor. But his fame really thundered when he became a brave and very formidable pirate. In the 16th century, he made quite a few voyages and took part in a considerable number of battles.

Golden Doe

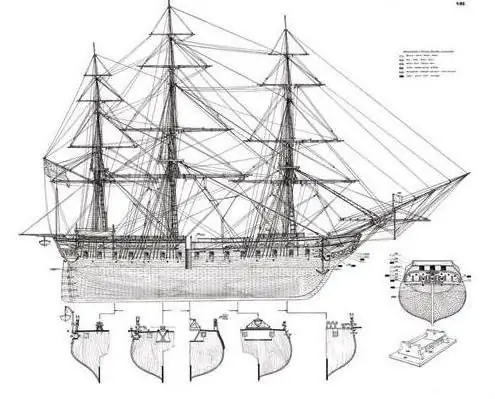

At the dawn of Francis Drake's fate, several sailing ships arrived at his property. Its main flagship wasship "Pelican". This ship was a five-deck three-masted ship. On board there were 20 artillery weapons. All sorts of maritime stories rarely tell us that a ship that already has a name can be renamed, but it was with the "Pelican" that such a story happened by the will of fate. In 1578, Francis Drake changed the name of this ship to "Golden Hind" (in Russian, this name sounds like "Golden Doe"). It was under this second name that the ship was inscribed in sparkling golden letters in the world history of navigators. Francis Drake did quite a few dizzying deeds on it, which were later told in history and adventure books.

It is these wonderful ships that make many people assemble ship models from wood with their own hands. Drawings of many such structures can often be found on the Internet. So, inspired by the ancient history of navigation, we will learn from this article information on how to do something similar.

DIY wooden ship model: from start to rainbow horizons

In fact, the history of modeling consists of several stages. Moreover, each of these stages is associated with several features. A fan of miniature shipbuilding may need to be able to modify the available materials. It is also important to expand the choice of modeling objects. After it develops enough, then it can have mass production of models. The next step will be the developmentposter exhibition modeling from those sets that he already has. Subsequently, you can develop to the formation of individual segments. It can be anything - from ship models and in the flesh to copies of individual motorcycles, trucks, as well as all sorts of other cars.

DIY wooden ship models: drawings, instructions, tools

So, well, let's start creating such a ship. Carving prefabricated ship models from wood is not an easy task. You will need many tools for this. Among them are: a knife, a chisel, a hammer, a bar (and, if necessary, a saw), a thin cloth, superglue, a long wooden spire, a rope, a drill. In addition, you will need two more very important parameters. Firstly, it is time, and secondly, an important quality of those people who create prefabricated wooden ship models is patience.

Cutting a ship out of wood

First you have to work with a chisel. You have to file everything and remove the old bolts that have a flat head. It won't take you much time - just two minutes. In these two minutes, the pre-finished block will later become a boat. Now you need to clear the bar. You should carefully scrape off the bark. Hold the bar itself directly towards the tool. Let's take the standard design as an example for our small ship models, which we will build according to the principle below. Take those pencilssketch a preliminary sketch on the bar. Following this, process the bar with a sharp knife. The tilt of the blade itself should be at an angle of approximately 10 degrees. When planing, keep in mind that this is not the easiest job, so be patient. You should not forget that if for any reason you make a mistake, then it will be quite difficult to correct everything. Remove the chips layer by layer, while you should try and process the original bar as smoothly as possible. It is important that the top and bottom should be parallel.

Note that you don't have to throw out the shavings at all. The fact is that, in principle, it can be used as an additional material as a mulch.

The carving of the front and sides of the ship

Well, now we need to draw the front, bottom, as well as the back. We will cut them out in exactly the same way as above. It is necessary to make these parts even. In order for you to get the bow of the ship, you will have to saw off a piece from the front. Following this, you must round the saw cut with a knife. When you make the nose, try to tilt the knife blade itself back. It should be facing aft.

Drilling holes and subsequent installation of equipment

You should have some spiers. Therefore, drill a number of holes, they should be slightly larger than the beams themselves. It is important that there are not too many holes. Otherwise, you may develop a crack. And because of the crack, as you know, a severe disaster can occur - go to the leak. Do not use glue! If you do this, then further work will be much more difficult.

Setting the sails on the model

Decide, to begin with, exactly how many panels you want to get on your final ship. Let us take as a condition that we will have four panels for the first mast and the second, and three for the last. Following this, take a few wooden spiers and cut them. Cut the fabric into a trapezoid shape. Then start gluing them. Make notches on the branches of the sails, fasten each branch with a corresponding notch. Then glue the middle of the edges to the sails. Repeat the same for all masts. It's best if you build the rear mast first, then the middle one, and then the bow one.

Now let's install the upper flying sail. Cut out a kite shape from the fabric. Take the thread and attach it to the opposite corner of the cloth. Leave ends on either side for all corners. Glue a small piece of thread exactly on the top of the boat. It should be slightly higher than the bow of the boat itself. From the opposite corner, measure up to the middle of the lower branch of the sail on the forward mast. Then cut off the very thread that you measured and glue the tip to the appropriate place.

On each side you mustleave some threads. Pull them back and glue them straight inside the boat. Then you can cut off the excess rope. Create and attach the back panel in the same way. It must be attached to the back of the rear sail. Measure, cut, and make sure it fits over the two lugs. Then glue them in the corners.

Well, now you've learned how to make simple ship models out of wood. And although everything in this article is described only in general terms, we hope that it will help you in your future career as a "shipbuilder". Unless, of course, you are interested in it. Trust me, it's worth it!

Recommended:

Wood carving, contour carving: description with photo, work technology and necessary materials

Artistic woodcarving is one of the oldest techniques of decorative art. During the history of the existence of the craft, several of its varieties have appeared. One type is contour carving: an exquisite technique used when working with wood

Wood carving, flat-relief carving: description with photo, sketches, necessary tools and work technique

Flat-relief carving is an exquisite and unique woodcarving technique that comes from the 18th century. Types and methods of performing techniques, necessary tools and sketches of ornaments. The history of the appearance of the craft of woodcarving in flat-relief technology

Wood carving, house carving: description with photo, work technique and ornament patterns

Facades made in ethnic style are distinguished by bright folk craft - house carving or woodcarving. The unique craftsmanship originated centuries ago and has been greatly improved over the years. Existing work techniques allow you to create aesthetic decorative elements to decorate buildings

Sailboat models made of wood

Sailboat models can be made in a variety of variations. And in order to make them, you need to take into account some basic points. And that's what this review is about

DIY wood box: master class and drawings

It is not easy to make such an accessory as a wooden box with your own hands. But this is a very, very exciting activity! And the result, with some skill, can be pleasantly pleasing to the eye. We will tell you what the sequence of operations for such work is, and what tools you have to use