Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:46.

- Last modified 2025-01-22 22:09.

Genuine leather has been used in various areas of human activity since ancient times, since even then animal skins were needed to protect against the cold, and besides, it was the most affordable material of all possible. They were originally cured with fire smoke, but this could not keep the skin intact for long.

Then man began to use various herbal substances in order to make the skin stronger, more elastic and keep it for a longer period. Now the world produces a huge number of varieties of leather, each of which is suitable for certain purposes. Accordingly, depending on the desired result, it is produced in different ways. In particular, there is such a way of processing it as crust, which will be discussed in more detail in this article.

Leather treatment in brief

Treatment of natural leather usually consists of three stages. First, preparatory actions are carried out, when the skin of the animal is cleaned,soaked in various solutions, treated from hair and fat layer and softened. The most popular and convenient types are the skins of livestock, of which the most common are calf, pig and sheep. But at all times, the skins of exotic animals were also popular - snakes, crocodiles, because of their unusual appearance.

Now products made from similar materials also remain popular, but since hunting for reptiles used to be so common that they were in danger of extinction, modern manufacturers often use artificial leather or natural leather with an imitation of the necessary pattern, fortunately, modern processing technologies allow it.

The next stage - tanning - is carried out to give the skin stability, strength and elasticity, the main properties of high-quality genuine leather. At this stage, the material is soaked in special solutions that contain chromium, aluminum, vegetable and artificial tannins, or combinations thereof. Suede, for example, is obtained by treating leather with fatty acids. At the end of this operation, it looks like a finished semi-finished product, but additionally, depending on the variety, other processing can be carried out.

At the last stage, the skin is trimmed with various methods to give an attractive appearance to its front surface - planing, covering (that is, surface) or deep staining, pressing, polishing and others.

Types of leather

Over the years of development of the leather business, a huge number of types of leather have arisen: saddlecloth, husky,crust leather, yuft, chevro, suede, shagreen leather, velour, etc.

Fields of leather use

So, for the manufacture of haberdashery products (mainly gloves) they use husky, which is created from the skins of lambs and after chrome tanning becomes soft, elastic and very pleasant to the touch. They are also made of suede, the front surface of which is covered with a low soft pile. Due to this feature of the surface, it is difficult to clean, gets dirty faster, stains can form on it when moisture gets in, and it also wears out faster than other types of genuine leather. Therefore, usually suede products are not intended for everyday use, moreover, they have a very advantageous appearance - stylish and noble.

Bags, wallets and belts are made from yuft (the so-called "Russian leather"), which comes in different thicknesses and properties, depending on the material from which it is made - usually the skins of cattle. In any case, this type of leather is characterized by high strength and softness; yuft gets such properties after processing with plant components. Men's belts are sometimes made of saddlecloth - this is a very tough leather, which is characterized by increased wear resistance.

To create shoes, various types of leather are used, depending on the purpose of the shoe. Most often, this is its smooth variety - expensive high-quality products are made from it, since the material itself has high characteristics. Shoes and boots are often made of patent leather, which does not allow the feet tobreathe, but looks expensive and neat. Suede and other types are also used for the production of shoes.

For jewelry, craftsmen use either soft and thin types of leather, or, if it is necessary to leave an imprint on the product, harder ones, for example, yuft or saddlecloth.

Rare leather

It is worth remembering separately parchment, which in the modern world is used much less frequently than before - in bookbinding, for jewelry and musical instruments, in a word - in specific activities. In the past, it was the main material for creating handwritten books.

What is a crust?

Crust is a tracing-paper from the English word "crust", which translates as "crust".

How is crust leather processed?

After the initial sorting of the skins of cattle, they begin to soak. Crust is distinguished by several features here: when it is processed, a large amount of chromium and water is used, which makes it possible to make the skin supple and soft at the same time, and, moreover, it is necessary to comply with environmental requirements.

At the next stage, the skin is dyed using the drum dyeing method. Thanks to modern methods, the dye penetrates the skin and thus gives through dyeing. For this reason, you can not be afraid that the top painted layer will crack.

On the reverse side of the workpiece, an imprint of the drum mesh may remain due to the specifics of the coloring method. The front surface is not trimmed, so genuine leather is crustit has a natural pattern on it, which is why it is sometimes difficult to distinguish high-quality crust from smooth leathers. In addition, the lack of processing of the front surface allows you to avoid subsequently many of the disadvantages associated with destruction and delamination. Also, the skin is characterized by increased resistance to water, which occurs during the tanning stage.

Krast uses

The special qualities of crust leather allow it to be used in the production of a variety of items. This material is quite strong, but at the same time malleable and light, and besides, it is durable. Therefore, it is used in the manufacture of bags, shoes, haberdashery, various stationery and even furniture. In addition, leather craftsmen, among other types, choose crust leather for embossing, as its texture is best suited for such a finish.

Crust care

Care for this type of leather is necessary, given the characteristics of its surface. Washing the crust does not make sense, since it is waterproof, and will only lose some of its strength and aesthetics. But it can be cleaned of dust with a dry cloth, and if dirt appears on the product, it is better to remove it with slightly alkaline cleaning solutions applied to a soft sponge. After wet cleaning, the product must be thoroughly wiped. From time to time it is worth using special products to lubricate the crust with a breakdown, which will retain the elasticity and strength of the material.

Small scratches that inevitably occur whenWith frequent use of the product, the crust is able to heal itself due to the fact that the natural pattern of the skin is preserved - scratches smooth out from friction and eventually disappear completely. On folds and in areas of high friction, the color of the leather may darken, giving the appearance of aging and quality.

Recommended:

DIY leather bracelets: master class

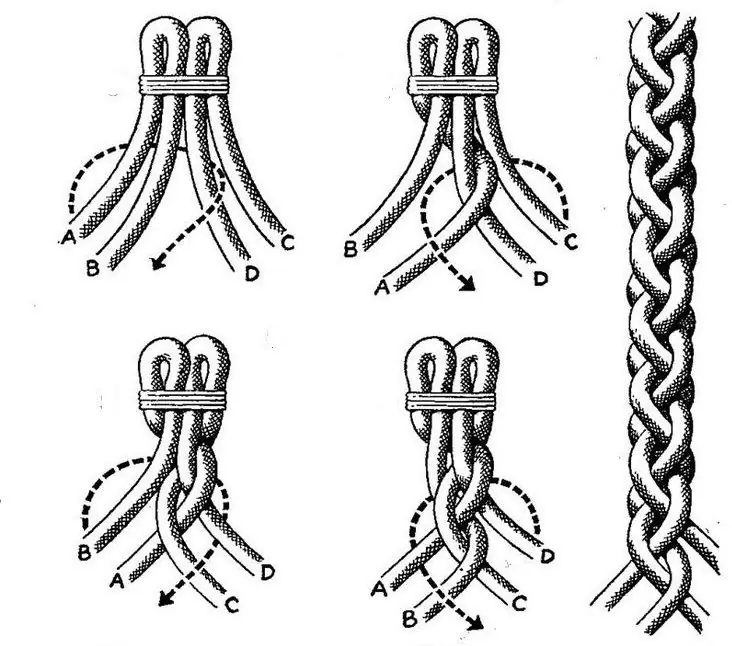

Bracelets are presented on store shelves in a wide range, so choosing a stylish addition to the image is not difficult. However, many prefer exclusive jewelry, so they decide to try their hand at creating accessories. Making a leather bracelet with your own hands is quite simple, even a novice craftswoman can handle it. In this material, we will tell you in detail how to weave women's and men's bracelets, what materials will be needed for work

Artistic leather processing: history, techniques and features

Leather is a natural, environmentally friendly material that is flexible in work. It is soft, pleasant to the touch, durable. Working with it allows you to show your creativity and create unique products from unnecessary, old things. In the article we will consider what is the artistic processing of the skin

What can you do with leather with your own hands?

Everything new is old well remade. Therefore, many needlewomen use improvised materials and their remnants to create their works. They rarely have the question of what can be made from leather, fabric or the remaining beads. When looking at pieces of material, another original idea almost immediately flashes in my head

DIY leather goods for beginners: photo

People can be divided into two types: the first throw away all unnecessary or broken things, the second put them away until better times or for further restoration. Often, among all such goodness, things made of leather, natural or artificial, come across. Not always a shabby little thing can be restored. Therefore, a completely logical question appears in my head: what can be done with this material?

Do-it-yourself leather passport cover. Step-by-step instruction

Sometimes you want to have an interesting accessory. Not even because someone else doesn't have one, but simply for their own aesthetic pleasure. If you like a thing, then it is pleasant to use it, the mood rises. Also, sometimes you want to create something with your own hands, such a thing is doubly interesting, because the soul is invested in the work