Table of contents:

- Author Sierra Becker becker@designhomebox.com.

- Public 2024-02-26 03:35.

- Last modified 2025-01-22 22:09.

To add a twist to the design of your home or to prepare an original gift for a loved one, master classes will help you learn how to make gypsum vases with your own hands. First, it's pretty simple. And secondly, you can create gypsum vases with your own hands according to your own design. And then you get an absolutely exclusive thing.

Vase made of cloth soaked in gypsum mortar

This manufacturing option is the easiest. The master will need a piece of unnecessary matter. Immediately before work, a plaster solution should be prepared.

The fabric is dipped into it and hung on a bucket, post, stump. It is only important to think in advance that the bottom of a do-it-yourself gypsum vase should be stable and even. Therefore, it is recommended to stuff something on the upper part of the column of small thickness that increases the diameter of the base of the future craft: a plate, a pot lid with the handle down, a cut out square or circle made of plastic or wood.

A rather creative gypsum vase will be ready in a few hours. Making it with your own hands is not at all difficult.

Gypsum vases from scrap materials

Most often, when working with plaster, masters use the casting method. In order to make a vase from plaster with your own hands using this technique, you need to choose the right shape. It is not necessary to prepare the mold specially. You can find something suitable among scrap materials.

For work, use the main container of the desired size. It can be a plastic or glass bottle, box, container, tall beer glass.

It is also necessary to take care of the details, thanks to which it will be possible to make a recess inside the vase. It can be of any shape. Only here the master needs to pay attention to its size: too large can lead to the fact that the walls of the vase will turn out to be too thin.

If a figured mold with a narrow neck is used for casting, for example, a bottle, plastic or glass, then after the gypsum has hardened, it will not be so easy to remove the craft. Plastic can be cut and removed. And the glass containers will have to be carefully split so as not to damage the do-it-yourself plaster vase.

Master class

Here, the technique of casting a vase with a rectangular base is discussed in detail.

To make it, you will need a container: a box of milk or juice, a container, a box, a box. It is important to choose the right size shape. In this case, a plastic container is used forgrain storage.

You should also take care of the part for the notch. It is convenient to take a glass or a glass bottle with a diameter smaller than the pouring mold.

- In a larger container, place the piece to be removed. It is held in such a way that it does not touch the bottom of the mold.

- Gypsum diluted with water is carefully poured into the void between the mold and the part to form a recess.

- Then you should wait a while for the plaster to harden slightly. During this period, the recess part is kept in a suspended state.

- When the mass "seizes", the structure is left until it hardens completely. Then the vase is taken out, the irregularities are polished with fine sandpaper.

You can leave the vase white - it's very stylish. But if the master has a desire to paint the craft, make a drawing on it, then you should not resist him. The finished vase can be varnished.

Making molds for casting

Often you want to make a vase of a certain shape or repeat an already finished one. Then the master himself makes a mold for casting from a solution of gypsum or silicone sealant.

- A container is taken slightly larger than the object from which the form is removed. She will act as a formwork.

- A mass (gypsum mortar or silicone sealant) is poured onto the bottom of the container.

- After hardening, the object itself is laid sideways on the resulting layer.

- The mass is poured exactly to half.

- The design is left alone for a while.

- Can be made in not yet completely hardened mass of recess. These will be the “locks”, thanks to which the parts of the mold will fit exactly during the casting of the vase itself.

- Next, the structure must completely harden. This will be one part of the mold. You can check if everything turned out right at this stage by removing the template from half of the mold. Then, the mold release template needs to be put back in place.

- The upper layer of half of the mold is greased: glycerin, petroleum jelly, oil, cream.

- Fill the entire template with mass so that it disappears completely.

- Wait until the mass becomes as solid as possible.

- The mold halves are taken out of the container, separated from the template from which the mold was removed.

Gypsum floor vases

Now you can start casting. With the help of such molds, do-it-yourself gypsum floor vases are made.

First, the halves of the form are connected and fixed by wrapping with twine, tape, electrical tape. The filling principle is similar to that described in the "Master Class" chapter.

The resulting craft is covered with paint, varnish or a drawing is applied. If desired, the vase is left white.

Creative Lego molds

You can design your own vase. For example, to assemble a layout from Lego constructor parts.

Next, you need to make a mold according to the method described above and produce a plastercasting.

Recommended:

Gypsum flower: necessary materials, job description, photo

Very often you can see plaster bas-reliefs on the wall in the interior of houses. Or cute figurines made of similar material, chic candlesticks and much more. This beauty always delights and makes you want to have such decorative elements in your home. This begs the question: how much does it cost and is it possible to make such beauty with your own hands? Of course you can. There are several simple options for making plaster figures

Acrylic gypsum: description, features, types and applications

Acrylic plaster celebrates 50 years of utilitarian use. Details of decorative interior decoration with imitation of natural gypsum and ornamental stone are used by builders and designers

Cold porcelain without cooking. Manufacturing methods

Cold porcelain without cooking is a great alternative to modern modeling materials. It is easy to make at home with minimal time and material costs. Flowers, figurines, dolls created from it cause genuine admiration

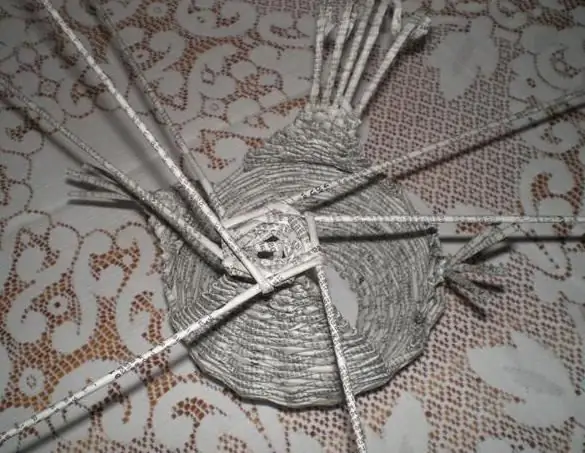

Weaving from newspaper tubes. Spiral weaving wreaths, vases, Christmas trees

In this article we will talk about how weaving from newspaper tubes takes place. Spiral weaving is a very exciting activity. Moreover, it is inexpensive and very simple

How to make vases from glass bottles? DIY vase: step by step instructions

Glass bottles fall into our hands quite often. Many of them have a very beautiful shape and texture, therefore, after the product is used, many people simply do not raise their hands to throw away such containers. Yes, in general, and you do not need to do this. After all, with enough imagination, a little patience and a share of effort, you can quite make something interesting out of them. We'll talk about this, namely, how to make vases from glass bottles