Inhaltsverzeichnis:

- Autor Sierra Becker [email protected].

- Public 2024-02-26 04:45.

- Zuletzt bearbeitet 2025-06-01 05:43.

Das Filzen einer Wolltasche beginnt mit der Erstellung eines Designs. Der Meister überlegt, wie es aussehen soll und welche dekorativen Elemente darauf vorhanden sein werden. Bedeutet es ein Ventil, einen Metallverschluss, Griffe aus Wolle oder einem anderen Material? All diese Details werden im Vorfeld bei der Erstellung einer Skizze ausgearbeitet. Je nach Anzahl der Ideen kann es mehrere Skizzen geben. Wenn Filztaschen aus Wolle das Vorhandensein eines Musters implizieren, müssen Sie das Material auswählen, um es im Voraus zu erstellen. Danach können Sie mit dem Erstellen einer Vorlage beginnen.

Bestimmung des Schrumpffaktors

Bevor Sie mit der Arbeit beginnen, ist es wichtig, den Schrumpfungskoeffizienten für die Wollarten, aus denen der Beutel hergestellt wird, zu berücksichtigen und zu berücksichtigen. Bei unterschiedlichem Material wird es unterschiedlich sein, daher ist es wünschenswert, den genauen Wert in der Praxis herauszufinden undfühlte zuerst ein kleines Stück.

Am häufigsten verwenden Handwerker kardierte Wolle oder Merinowolle. Das Material der Trinity-Fabrik ist bei russischen Spezialisten beliebt. Es produziert verschiedene Arten von Wolle zum Filzen. Wenn Sie bereits Erfahrung haben und im Voraus wissen, welches Ergebnis Sie von einem bestimmten Hersteller erwarten können, greifen Sie am besten auf dessen Produkt zurück.

Wenn eine Mischung aus Merino- und Trinity-Wolle für die Arbeit verwendet wird, beträgt das Schrumpfverhältnis ungefähr 45-50%. Bei der Verwendung zum Filzen von Taschen aus lettischer kardierter Wolle müssen 35 bis 55% aufgetragen werden. Viel hängt von den Fähigkeiten und Fertigkeiten des Meisters ab. Mit einer Schrumpfung von 50 % sieht das Produkt oft wie ein Fabrikprodukt aus.

Benötigte Materialmenge für die Tasche

Aufgrund der unterschiedlichen Schrumpfverhältnisse bei Wolle verschiedener Hersteller ist es schwierig, genau zu sagen, wie viel Material für ein Produkt benötigt wird. Für eine Tüte mit den Maßen 50 × 50 cm sind beispielsweise 300 Gramm in der Regel ausreichend. Für kleine Kosmetiktaschen und Clutches 20-30 cm breit - 100-140 Gramm.

Vieles hängt vom gewünschten Effekt und der Qualität des Fells ab. Wenn Sie eine starre Tasche herstellen möchten, die ihre Form gut beibehält, empfehlen Filzer die Verwendung von kardiertem Filz. Für feine Vorhänge und stromlinienförmige Konfigurationen benötigen Sie Trinity-Wolle, Merinowolle oder eine Mischung.

So wählen Sie das Material für die Vorlage aus

Nachdem Sie eine Skizze erstellt haben, müssen Sie ein Muster oder eine Vorlage zum Filzen von Wolltaschen erstellen. SeineDer Wert muss aufgrund des Schrumpfungsprozesses größer sein als die endgültige Größe des Produkts. Alle Muster werden um einen vorher berechneten Faktor erhöht.

Je nachdem wie dicht das Produkt geplant ist, können Sie unterschiedliche Materialien für Schablonen verwenden. Um ein Muster für eine nahtlose Filztasche zu erstellen, wird häufig ein Substrat für ein Laminat, eine Luftpolsterfolie oder eine Gewächshausfolie verwendet. Solche Optionen sind kostengünstig und für Nadelfrauen leicht zugänglich. Und Muster können mehrmals verwendet werden, was sehr praktisch ist.

Für dünne Filzprodukte ist auch eine 1 mm starke Laminatunterlage geeignet. Wenn es nicht vorhanden ist, können Sie eine Gewächshausfolie oder Luftpolsterfolie verwenden, aber letztere müssen vorher aufgeknallt werden, damit sie die Wolle nicht auseinanderdrücken. Für dichtere Produkte ist eine 3 mm starke Laminatunterlage geeignet.

Materiallayout

Für Anfänger ist es am besten, mit dem Filzen einer Wolltasche zu beginnen, indem sie verstehen, wie man das Material auslegt:

- In der ersten Phase teilen wir die Wolle in zwei Folien. Einer von ihnen geht nach vorne in die Tasche, der zweite nach hinten.

- Das Kammband wird quer ausgelegt.

- Zuerst kommt die horizontale Ebene und dann die vertikale. Der Vorgang wird mehrmals wiederholt, bis das Material aufgebraucht ist.

- Beim Kardieren wird am häufigsten auf die klassische Art des Layouts zurückgegriffen: in Lagen. In diesem Fall wickelt sich die Rolle ab, und je nach Zustand der Wolle muss sie zuerst in mehrere Teile geteilt werden, und dann sollten Streifen gestartet werden. Sie müssen diese Größe habenbequem in der Hand zu h alten.

- Danach beginnt das Layout. Es ähnelt dem gekämmten Splitter-Layout.

Nassfilzen eines Wollsacks: eine Meisterklasse

In diesem Fall ist es wichtig, die horizontale und vertikale Position beizubeh alten, damit die Wolle flach aufliegt:

- H alten Sie den Streifen mit der linken Hand, ziehen Sie mit der rechten Hand ein Stück heraus und beginnen Sie, ihn auf der Schablone zu verteilen, indem Sie ihn gerade richten.

- Hinter dem Rand der Schablone müssen Sie versuchen, 1,5 cm darüber hinauszugehen, Sie müssen die Wolle mit stumpfen Spitzen nach außen legen.

- Wenn das Material mit Seife durch das Netz gegen die Schablone gedrückt wird, bewegt es sich definitiv zur Seite. Seife zu Beginn der Arbeit kann flüssig verwendet werden, eine kleine Menge in Wasser verdünnen und am Ende zu Klumpen wechseln.

Mängelbeseitigung

Um das Entstehen von Lücken zu vermeiden, sollten Sie sich vorher absichern und selbst verschieben. Wir veranst alten einen „nassen“Workshop zum Filzen einer Tasche. Filzen aus Wolle geht mit speziellen Nadeln und ist recht mühsam, aber diese Methode gibt es auch.

Also, nach der ersten Reihe wird die zweite mit der ersten überlappt, mit einem halben Versatz, mit einem stumpfen Ende zum Rand der Schablone. Jede Reihe sollte die andere leicht überlappen, da sich sonst das Material löst und Löcher entstehen (wir erklären Ihnen unten Schritt für Schritt, wie Sie eine Wolltasche herstellen). Die Anzahl der Schichten hängt davon ab, wie viel Gramm Material für die Herstellung des Produkts benötigt wurden.

Notwendige Filzwerkzeuge

Der Prozess des Filzens von Wollsäckenbeginnt nach einem vollständigen Layout. Für die Arbeit benötigen Sie dann Handschuhe zum Schutz der Hände, Seifenlauge und ein spezielles Netz:

- Nachdem Sie das Produkt mit einem Netz bedeckt haben, müssen Sie die gesamte Oberfläche mit einer Lösung bestreuen, wonach der Watteprozess beginnt.

- In diesem Moment werden alle Mängel sichtbar - Gruben, Knicke und andere Unregelmäßigkeiten. Sie können korrigiert werden, indem an den richtigen Stellen Wolle hinzugefügt wird. Danach beginnen wir mit eingeseiften Händen zu rollen.

- Unsere Meisterklasse "Wie man eine Tasche entleert" kann nicht ohne Spezialwerkzeuge auskommen. In der Anfangsphase können Sie sich mit einer gewöhnlichen Plastikseifenschale selbst helfen. Sobald die Wollstampschablone entfernt wurde, funktioniert eine Seifenschale aus Keramik gut.

- Die Innenfläche ist mit einer speziellen Walzung behandelt. Und Sie brauchen auch einen Rubel. Es erleichtert spürbar das Filzen und wird in den letzten Stadien eingesetzt.

Der Vorgang kann mit Unterbrechungen mehrere Tage dauern. Wenn das Produkt nass ist, verschlechtert es sich nicht.

Entfernung des Primärbeutels

Das Material sollte fest um die Schablone haften, damit sie sicher umgedreht werden kann, ohne befürchten zu müssen, dass sich etwas bewegt. Nachdem Sie die gesamte Luft von der Oberfläche einmassiert und verdrängt haben, sollten Sie das Produkt auf die andere Seite drehen. Dann beginnt der nächste Filzvorgang:

- Du musst die Wolle über die Kanten der Schablone biegen und vollständig umwickeln. Die Arbeit beginnt auf der Rückseite.

- Hier ist zu beachten, dass beim Auslegen der ersten Reihe die Kanten bereits umgebogen sind und dort mehr Wolle liegt. Daher das ersteDie Reihe sollte versetzt sein, wodurch die Dicke des Produkts gleichmäßig wird. Dadurch entstehen keine zusätzlichen Nähte.

Vorlagenextraktion und Kantenverarbeitung

Die restlichen Ebenen sind ähnlich wie beim ersten Layout angeordnet. Um die Schablone herauszuziehen, müssen Sie die Kante des Halbzeugs auf besondere Weise schneiden und bearbeiten:

- Bei kleinen Wollstücken wird die Schnittlinie geschlossen, die Kante nochmals mit Hilfe von Seifenhänden und Maschen gepresst. Dabei unbedingt Handschuhe tragen, um die Materialschichten nicht zu verschieben, da sonst hässliche Narben entstehen.

- Wolle mit trockenen Händen verteilen. Nachdem Sie die Kante gedrückt haben, sollten Sie sie nicht zur Seite bewegen - filzen Sie den Wollsack einfach wie gewohnt weiter. An dieser Stelle wirkt die Seife wie Klebstoff und verbindet die Teile des Produkts fest miteinander.

- Griffe können auch geschnitten oder angerollt werden.

Das Produkt ist fertig!

Empfohlen:

DIY Blumenarrangements - interessante Ideen, Funktionen und Empfehlungen

Das Erstellen einer ungewöhnlichen Blumenkomposition liegt heute in der Macht aller: ein wenig Fantasie, ein bisschen Inspiration, ein Tropfen Wissen (oder die Fähigkeit, nach den richtigen Informationen zu suchen), Freizeit und die notwendigen Materialien . In diesem Artikel finden Sie interessante Hinweise zu möglichen und unmöglichen Skizzen zum Erstellen unvergesslicher Dekorelemente. Sie lernen die Nuancen dieses Hobbys (oder Berufs) kennen, wenn ähnliche Kompositionen für jemand anderen bestimmt sind

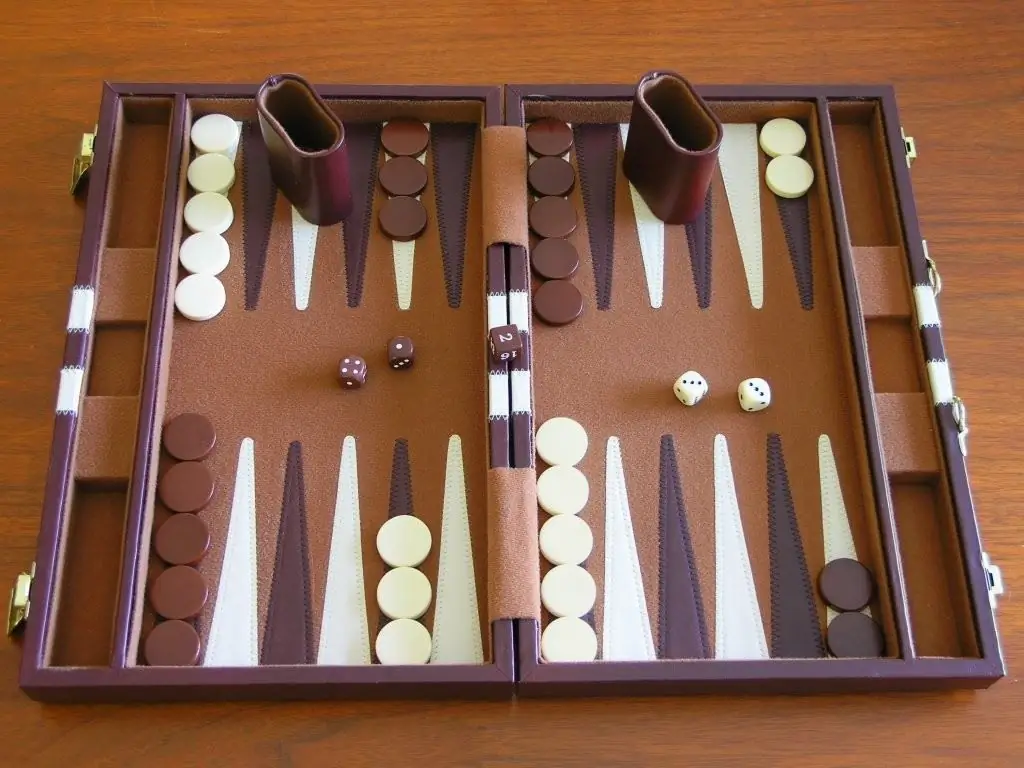

Wie man kurzes Backgammon arrangiert: Grundregeln, Funktionen und Empfehlungen

Die moderne Gesellschaft bevorzugt Gadgets als Unterh altung und vergisst Brettspiele. Aber solche Spiele wie Dame und Backgammon dürfen von Liebhabern des logischen Denkens in angenehmer Gesellschaft nicht vollständig verschwinden. Backgammon ist eines der ältesten Brettspiele. Weiter in diesem Artikel werden wir verstehen, wie man kurzes Backgammon richtig arrangiert, wie man die Regeln anwendet, Ausnahmen davon und vieles mehr lernt

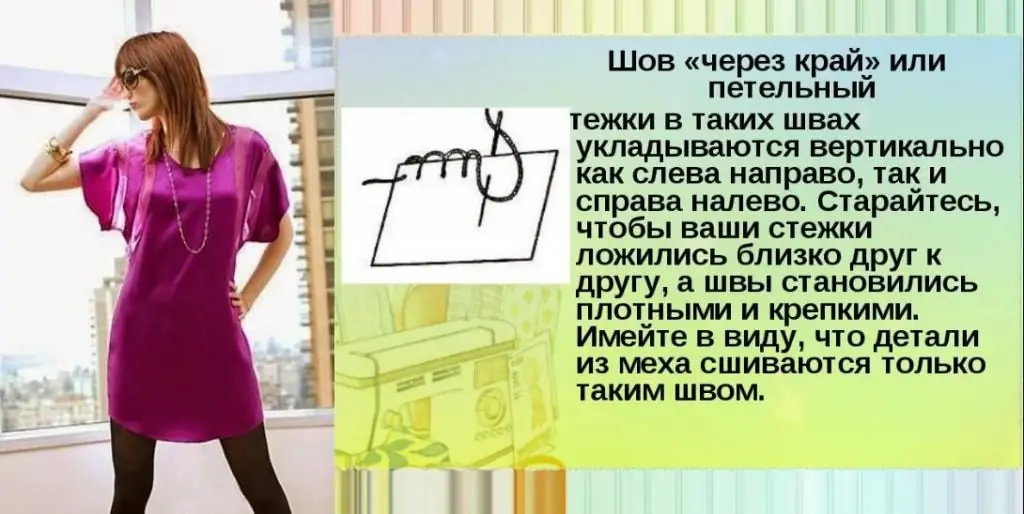

So nähen Sie schnell eine Tunika mit Ihren eigenen Händen ohne Muster: Funktionen und Empfehlungen

Es ist nicht immer möglich, Waren im gewünschten Stil und in der gewünschten Farbe in den Regalen des Geschäfts zu finden. Daher werden wir im aktuellen Artikel darüber sprechen, wie man eine Tunika mit eigenen Händen näht. Die Meisterklasse ist ideal für Anfängerinnen, sowie für diejenigen, die absolut keine Kenntnisse im Schneiden und Nähen haben

Wie man einen Pullover mit Stricknadeln strickt - Muster, Funktionen und Empfehlungen

Damit etwas wirklich Einzigartiges in Ihrem Kleiderschrank auftaucht, müssen Sie es selbst herstellen. Alle berühmten Couturiers geben zu, dass Handarbeit immer ein helles, individuelles Element eines jeden Bildes ist. Eine Sache wird eine Seele haben, wenn du einen Teil deiner eigenen hineinsteckst. Sie müssen kein großer Meister sein. Nachdem Sie die Grundlagen des Strickens erlernt haben, können Sie exklusive Strickjacken, Cardigans und Pullover kreieren

Wie man DIY-Geburtstagskarten macht - Funktionen, interessante Ideen und Empfehlungen

Die meisten Leute glauben, dass es unmöglich ist, eine schöne Geburtstagskarte zu machen, wenn keine teuren Materialien zur Hand sind, aber diese Meinung ist falsch. Es reicht aus, einfache Handarbeiten zu haben, um ein einzigartiges Meisterwerk zu schaffen